COVID-19…Asentics still at work!

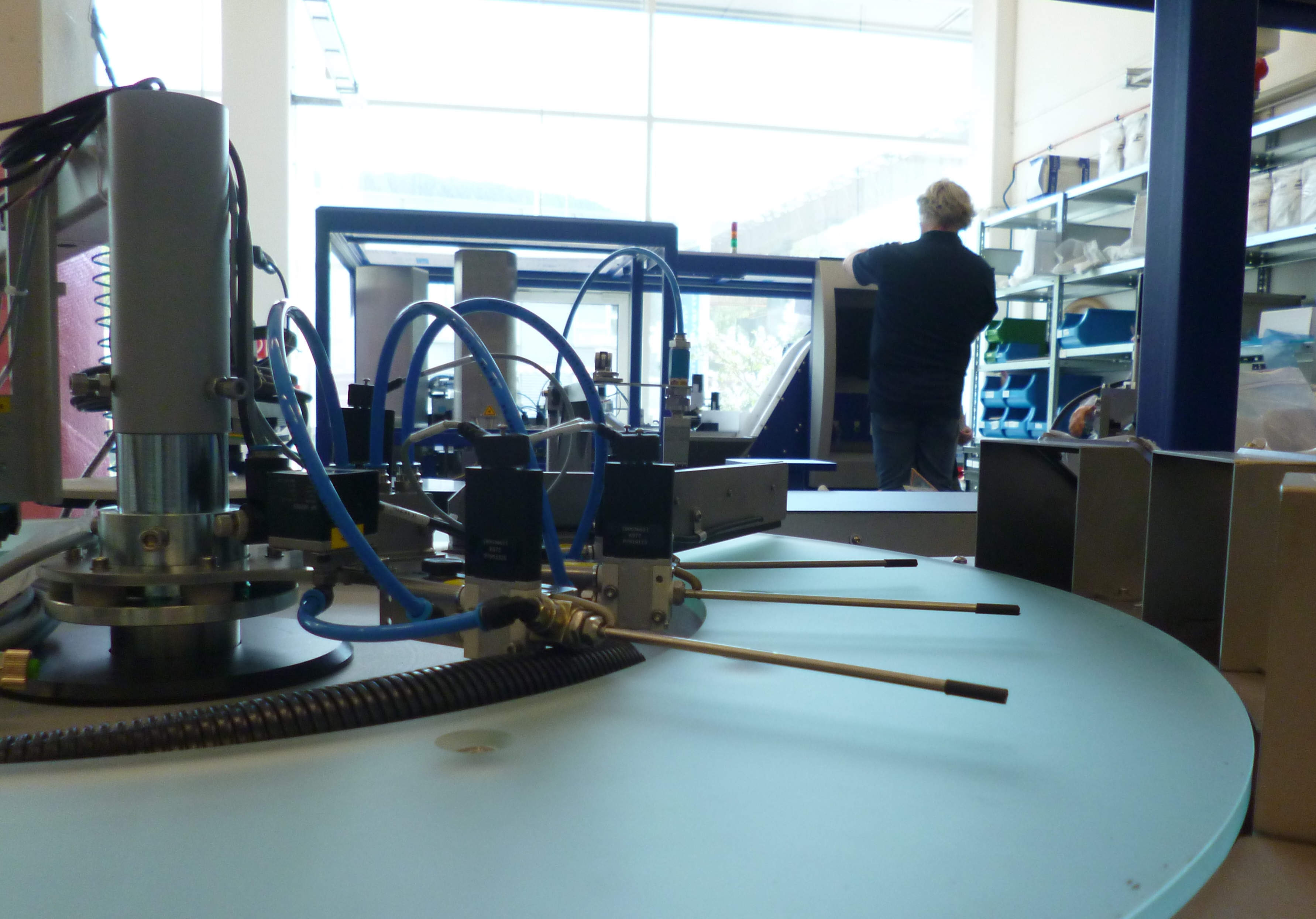

The COVID-19 pandemic is undoubtedly an enormous challenge from an industrial point of view. Asentics used the time to design the new BASIC 2, the little sister of the powerful inspection system Asentics VARIO. The first series is currently on the verge of delivery.

The Asentics VARIO in its various configurations is undoubtedly the flagship in the market.. It has been reliably testing elastomer seals and solid parts worldwide for decades, with its two glass plates and advanced camera sensors.

However, the market for sealing technology is diverse with parts that cannot be easily turned due to geometry or material and therefore cannot be tested on a inspection system with two glass plates and a turning station.

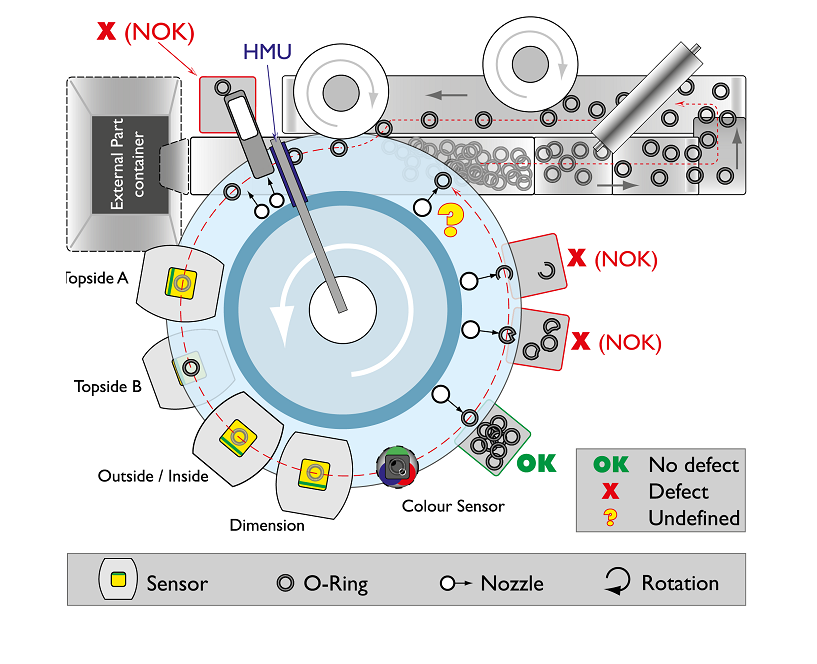

For this purpose, Asentics developed the new BASIC2, an inspection system with one glass plate and the same high-quality camera sensors of the VARIO4. These can be installed above and below the glass plate to ensure an optical inspection of both sides. With the right configuration, the BASIC2 can be seen as a simple and inexpensive variant of the VARIO4.

Features of the BASIC2 are:

The BASIC2 is suitable for all typical and round symmetrical seals made of rubber, but also frame seals, or seals such as dust caps that cannot be conveyed through a typical turning station. Also including two-component seals made of rubber, plastic or metal and solid parts, such as ceramic seals and sintered parts.

The BASIC2 can be equipped with the following camera sensors:

To save space, the feeder is integrated into the overall system and desgined for parts up to 70mm OD.

Depending on the part, a throughput of up to 12 parts per second can be achieved.

Of course, the BASIC2 is also equipped with all the useful Asentics features, such as a user-friendly interface, smart setup assistants and OPC-UA for Industry 4.0

For more information about the Asentics BASIC2, contact us via email, phone or our inquiry form.