Maximum efficiency,

no compromises in precision

no compromises in precision

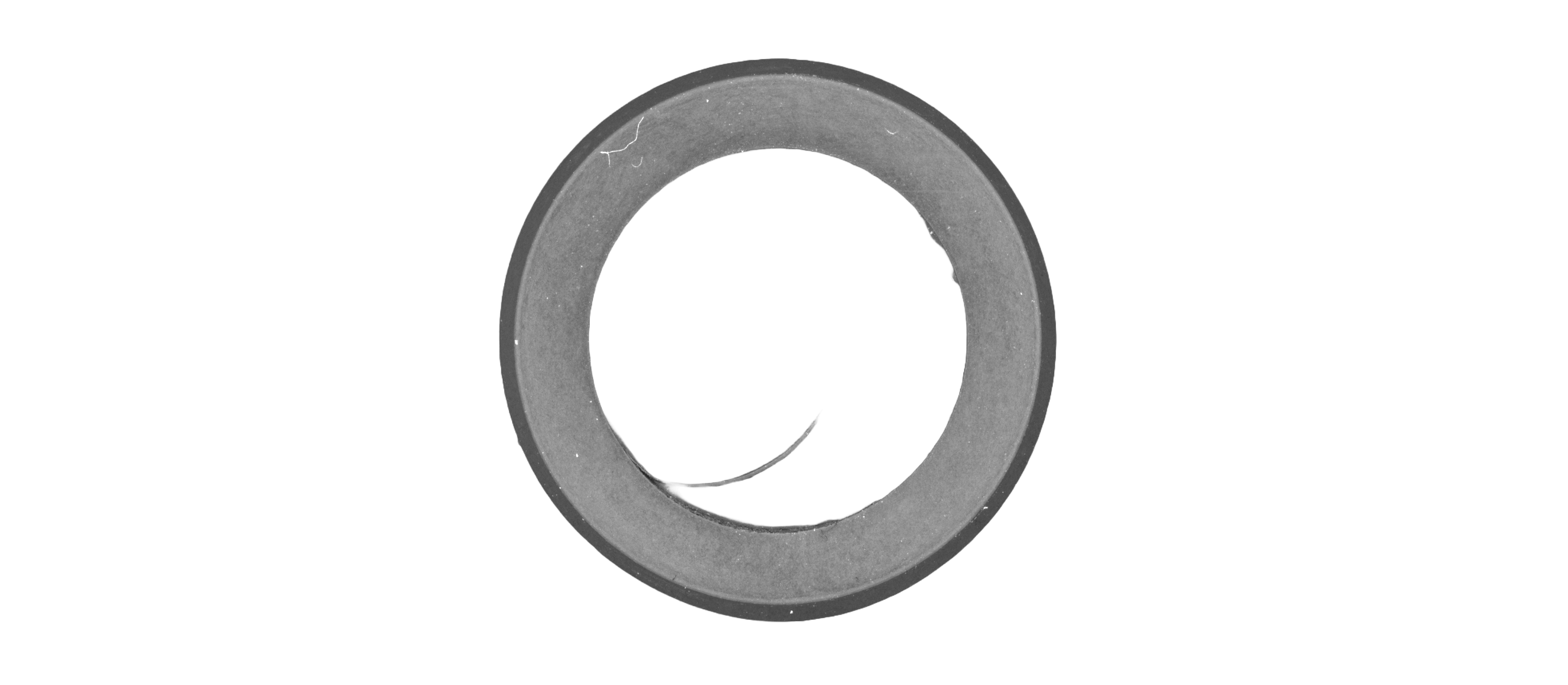

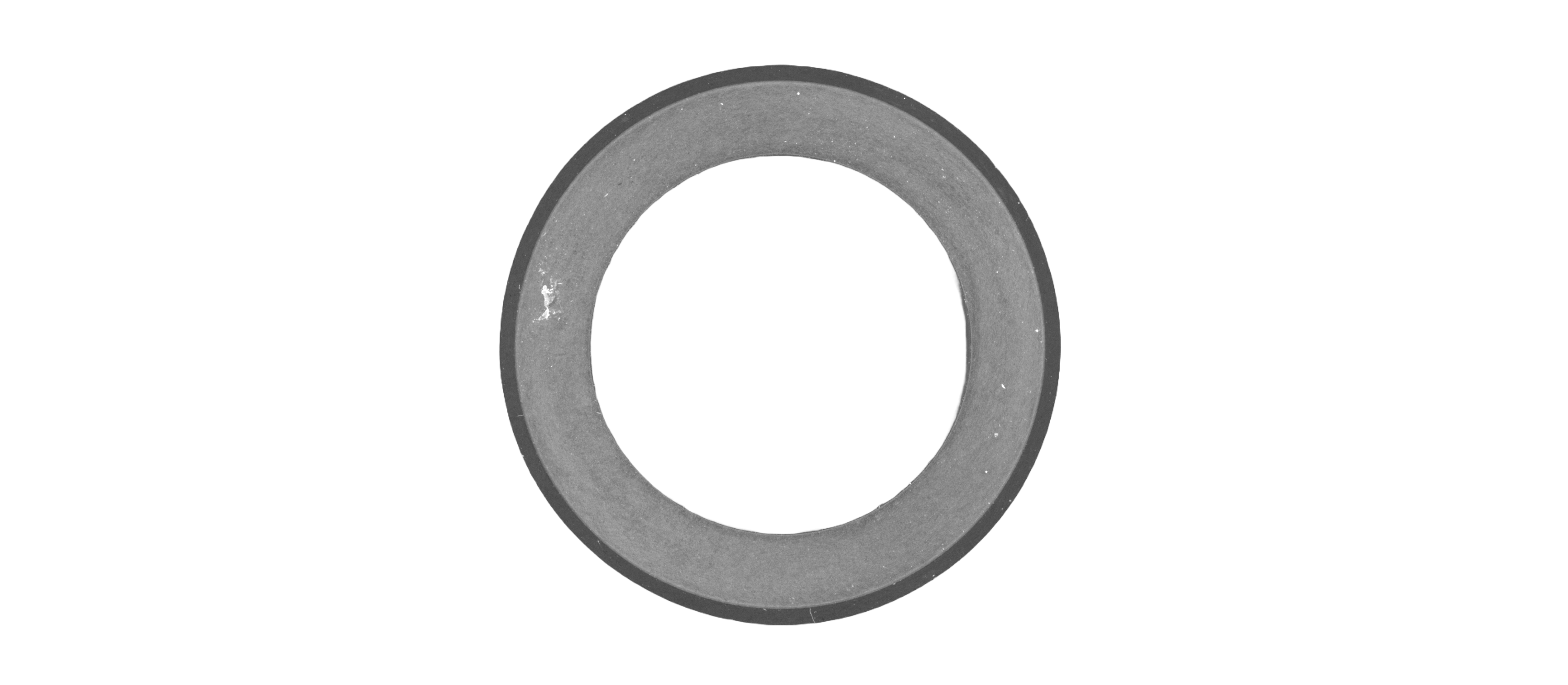

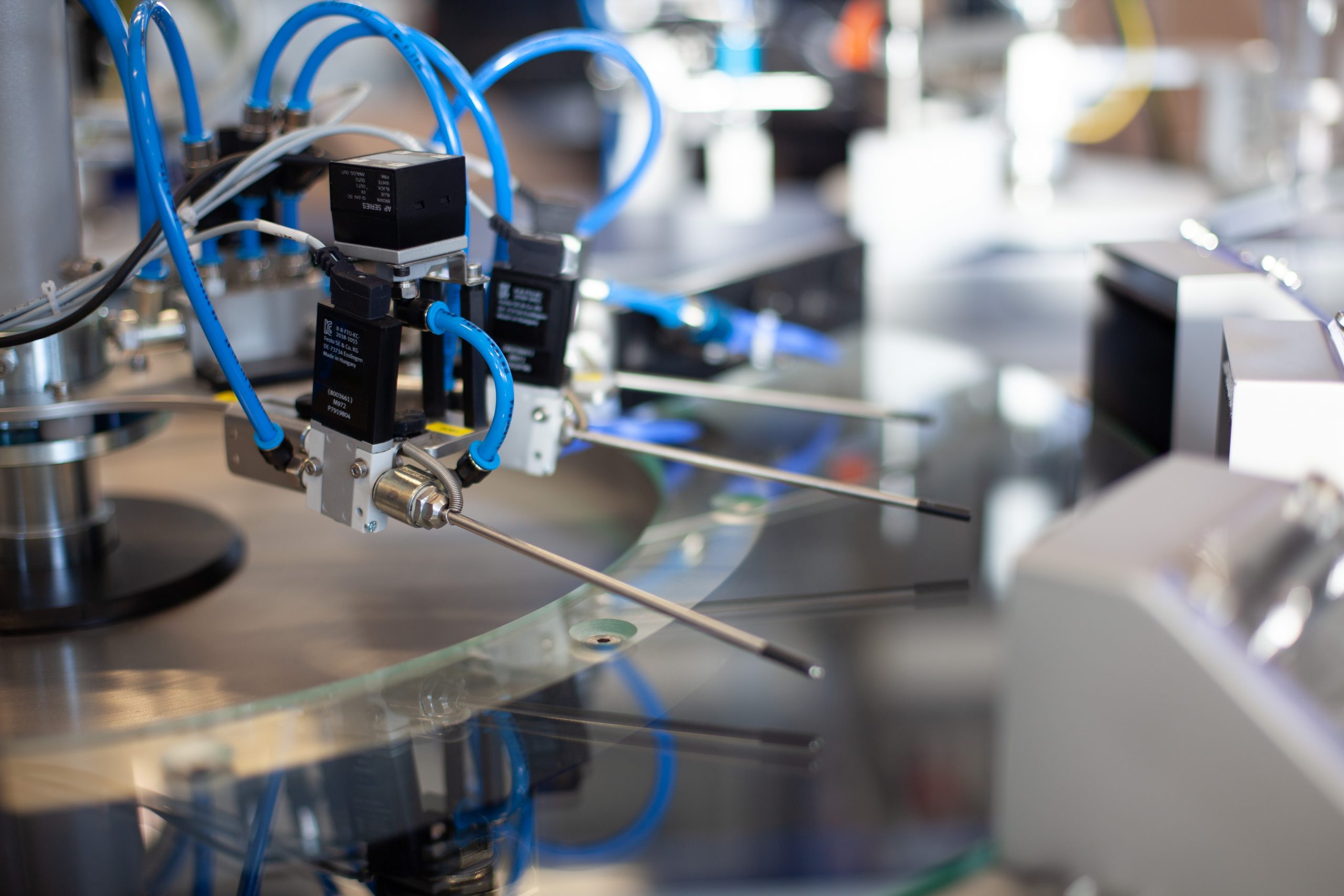

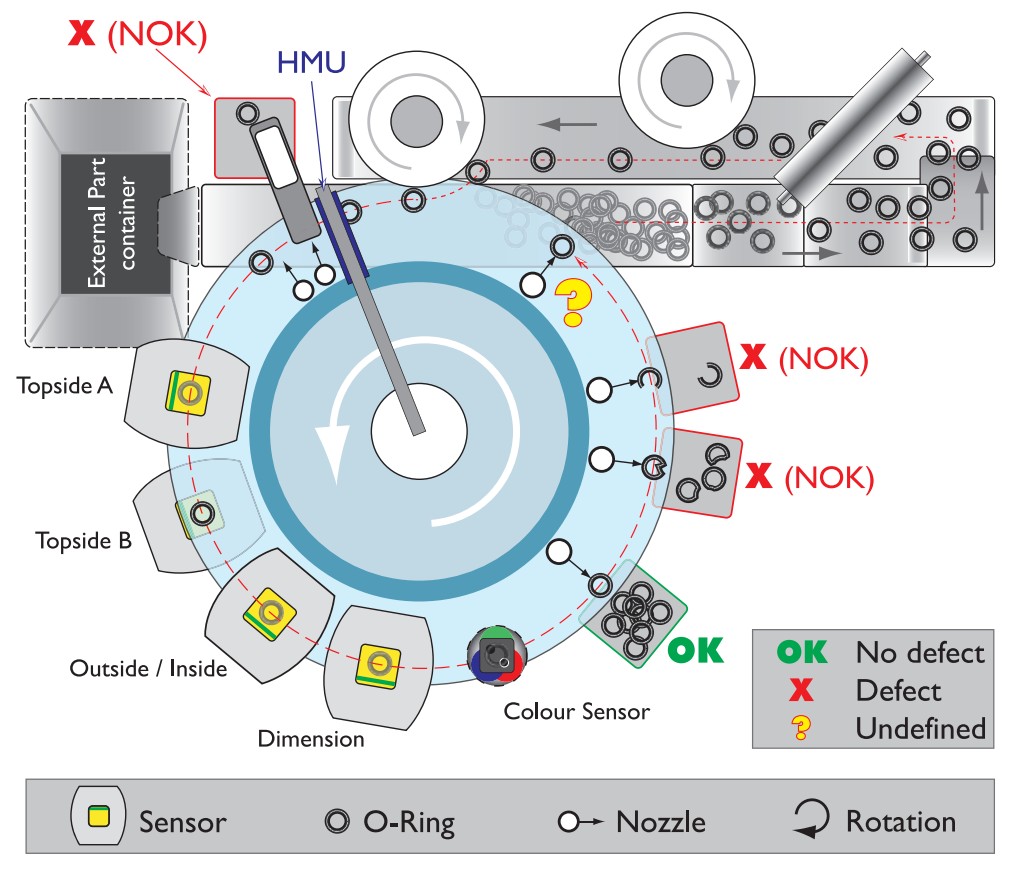

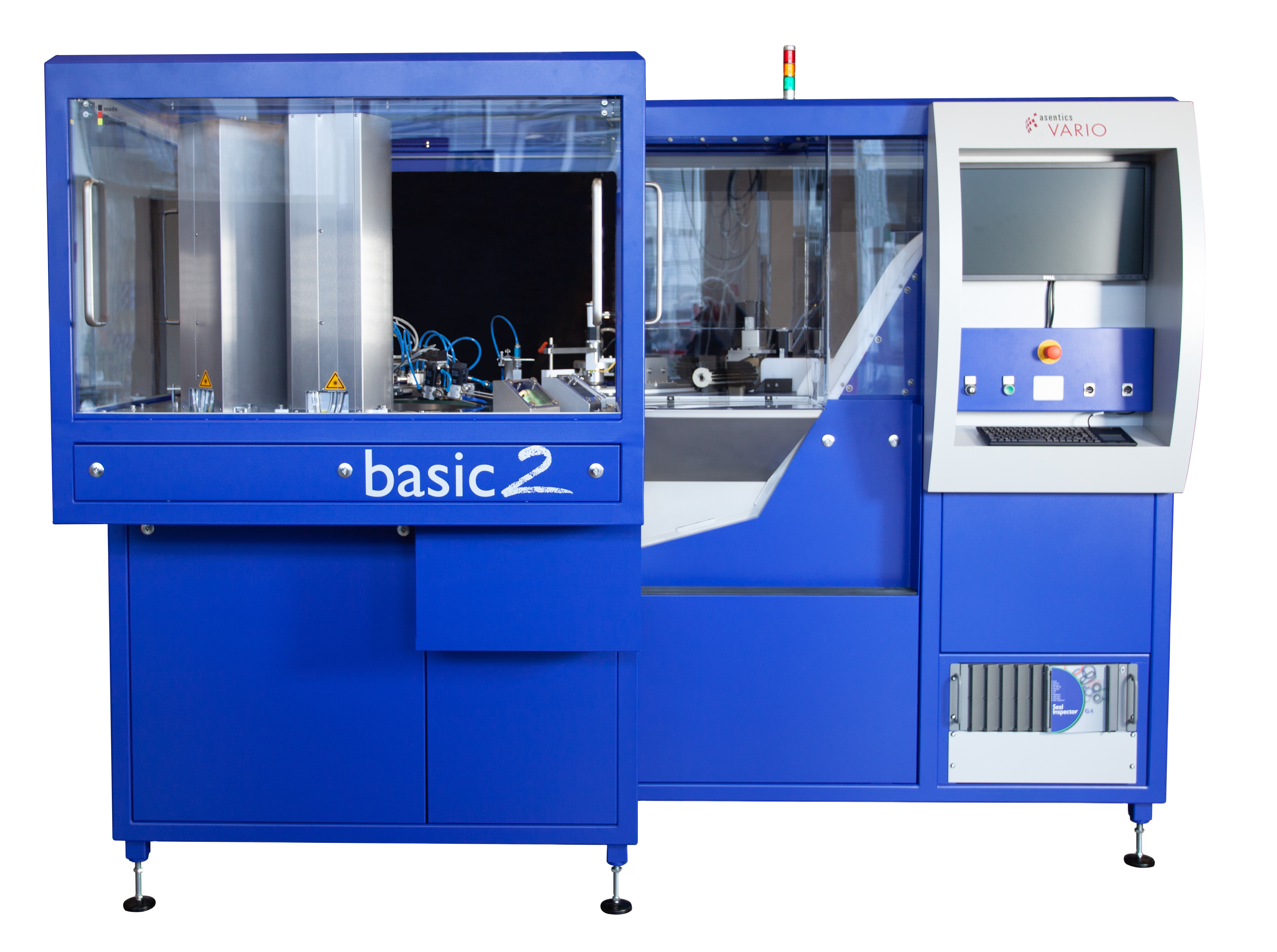

The BASIC2 combines high performance with maximum efficiency. Its innovative transport system with a single glass plate makes it ideal as a cost-effective inspection solution or for handling challenging seals with unusual shapes that cannot be turned. Equipped with up to six high-precision sensors, BASIC2 inspects each seal ring for surface defects, dimensional accuracy, and even hidden cracks—at an impressive throughput of up to 15 parts per second.

100% quality thanks to

industry-leading precision

industry-leading precision

At the core of the BASIC2 system are cutting-edge 12-megapixel high-resolution sensors that deliver exceptionally precise defect detection. Even the slightest surface defects or dimensional deviations are reliably identified – ensuring zero-defect production, maximum process reliability, and a measurable competitive advantage.

Full-scope quality control

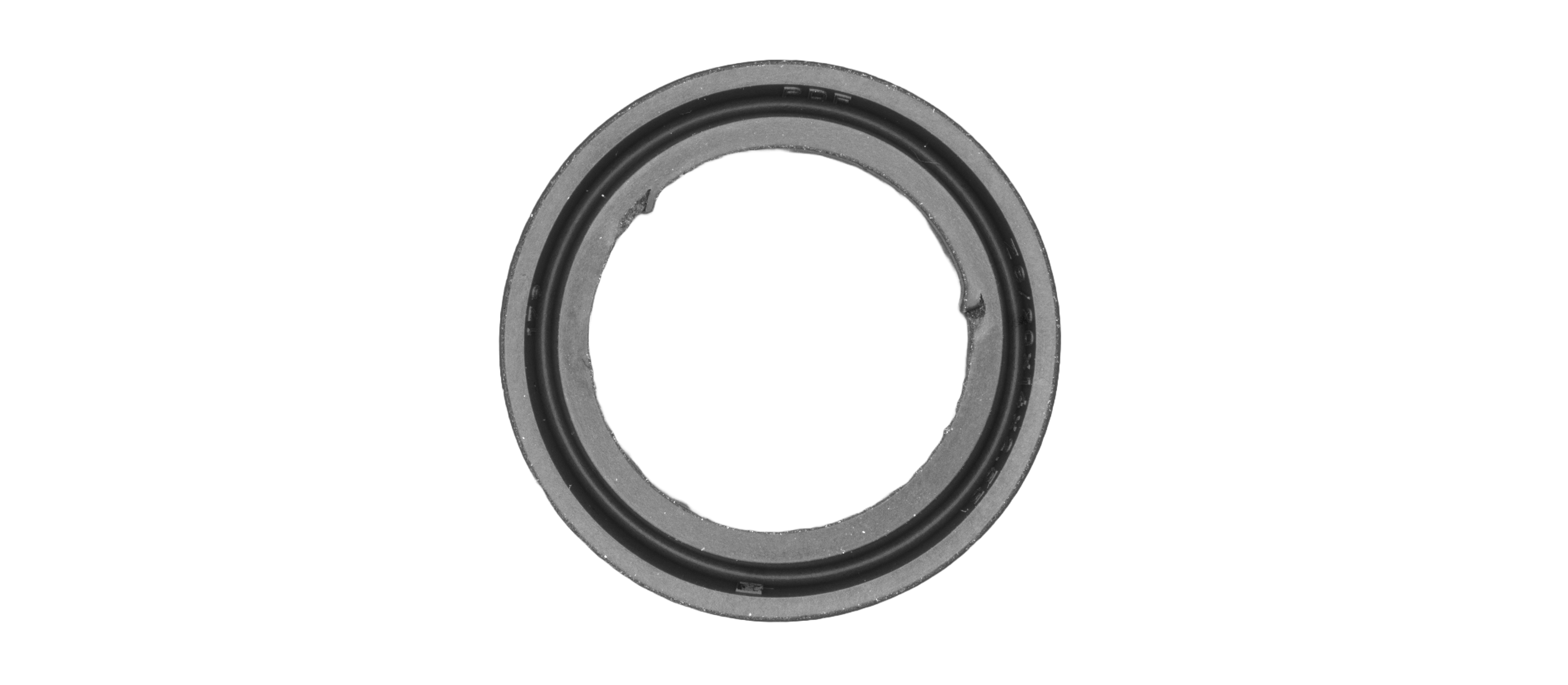

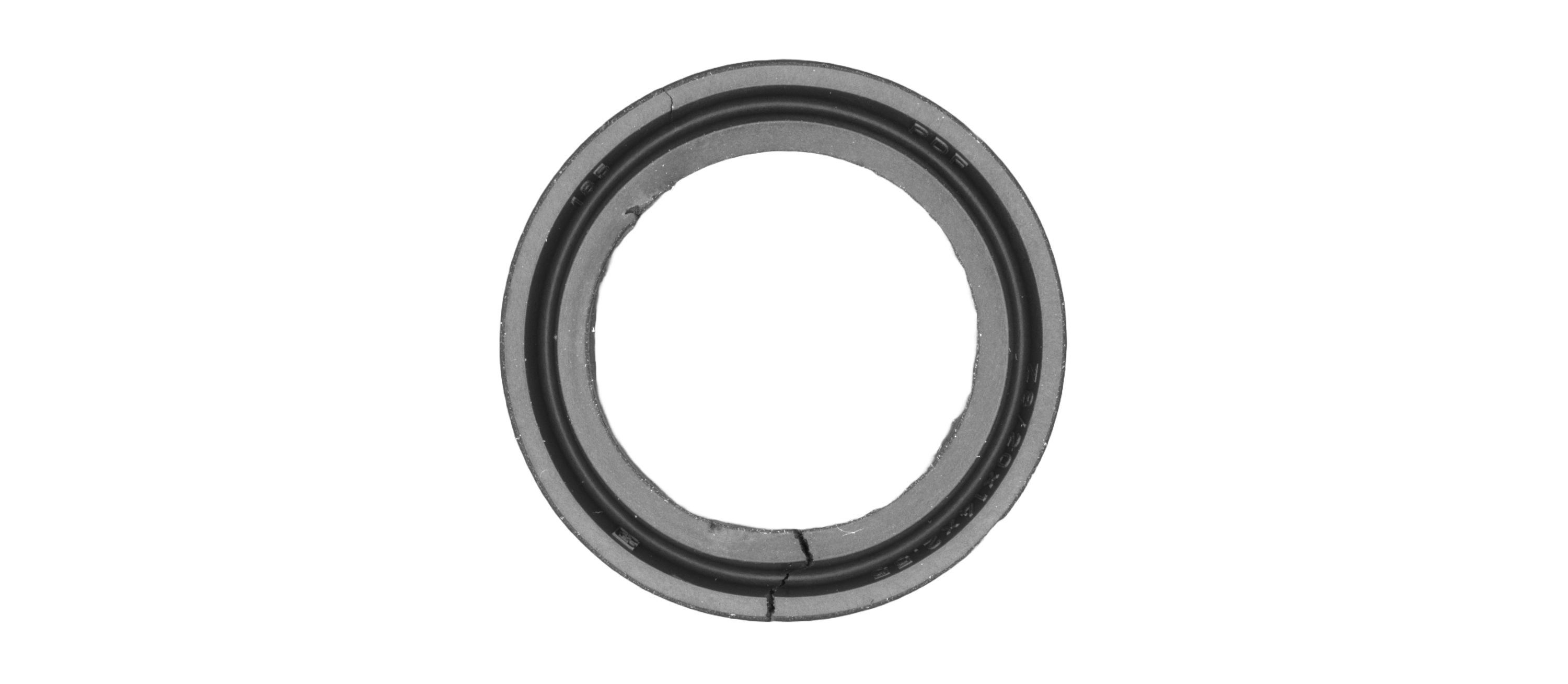

BASIC2 ensures reliable detection of a broad spectrum of seal defects – including surface damage, imperfections, contamination, as well as burrs and fine cracks.

Technology highlight:

FASTLINE™ crack inspection

FASTLINE™ crack inspection

For maximum product safety, the BASIC2 can be enhanced with the optional FASTLINE™ sensor – capable of detecting even hidden cracks that only appear under deformation. The result: high-end quality assurance that goes beyond standard inspection.

Designed for a wide range of seals

Tailored to your seals: The BASIC2 handles what standard systems can’t – from complex shapes and special materials to large diameters up to 70 mm. Even challenging inspection tasks are performed with consistent precision and reliability.

Flexibility in every aspect

BASIC2 can be quickly and easily configured for new product types. All the necessary parameters are stored digitally and can be accessed at any time, enabling quick set-up and reducing downtime.

BASIC2 also offers specific defect sorting (SDS). Defective parts are sorted separately based on the type of defect (e.g. surface defects, dimensional deviations or colour irregularities). This improves transparency regarding the causes of defects and supports the optimisation of manufacturing processes.

Custom-engineered

to fit your exact needs

to fit your exact needs

BASIC2 impresses with outstanding flexibility, offering extensive configuration options and a broad selection of high-precision sensors. From cost-efficient standard inspection to highly specialized applications for complex seals – the system adapts seamlessly to your specific needs.

BASIC2 at a glance:

Efficient inspection system for the 100% quality control of seals

Ideal for the inspection of seals with special shapes

High throughput of up to 15 parts/second

High-speed crack inspection with FASTLINE™ sensor

Easy configuration of new product types

Maximum investment security thanks to OPC UA and digital twin

Your BASIC2 is already waiting!

Whether you are just beginning to automate your quality control processes or have a particular application in mind, trust BASIC2 to ensure the quality of your seals. Our team will support you throughout the process.