Highest quality demands

for all sealing sizes

for all sealing sizes

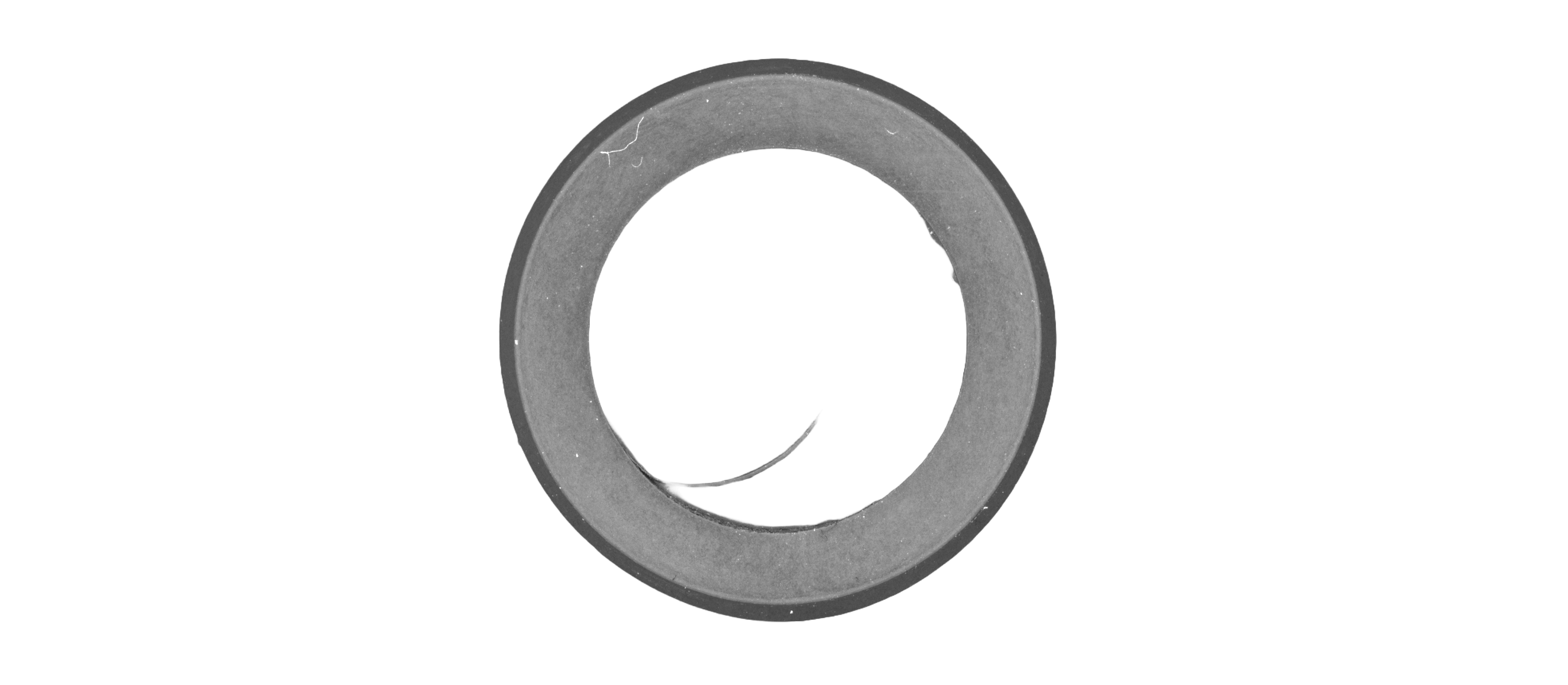

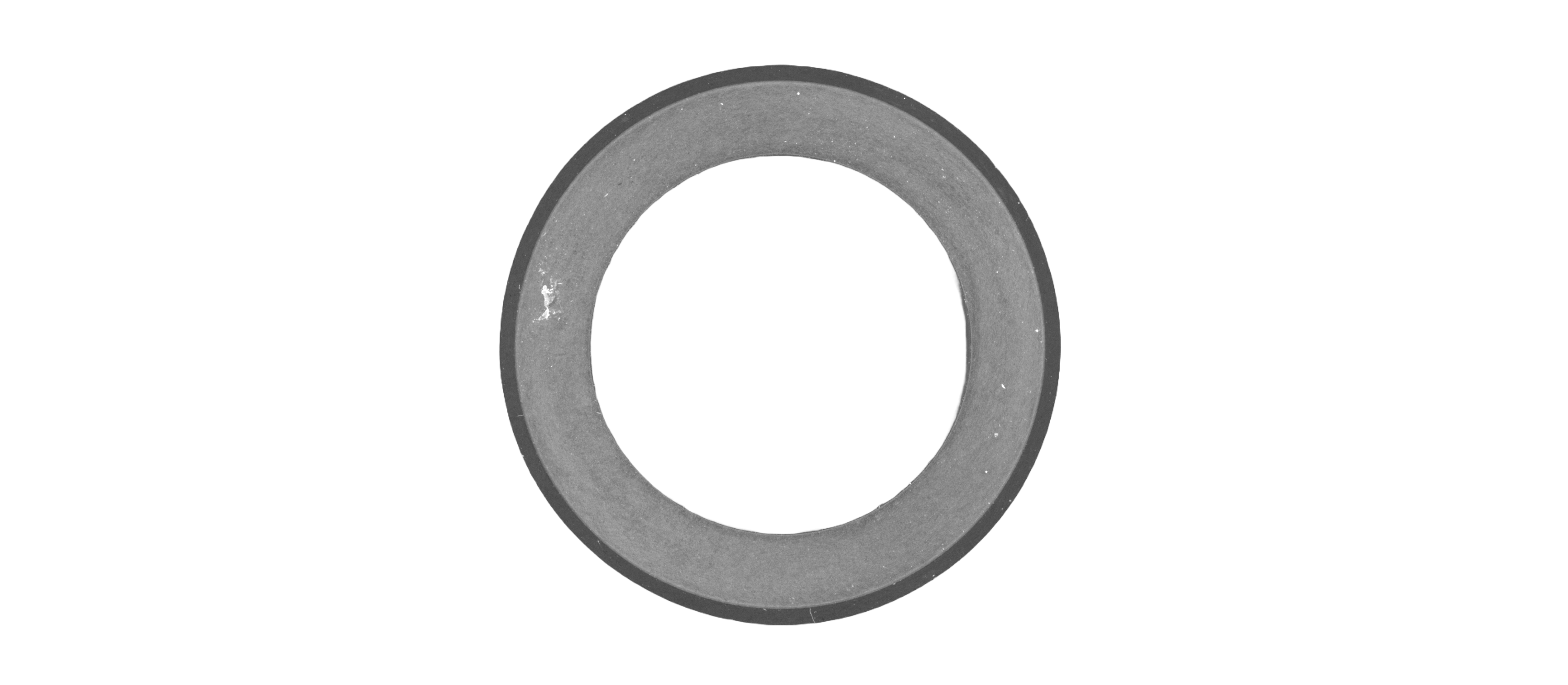

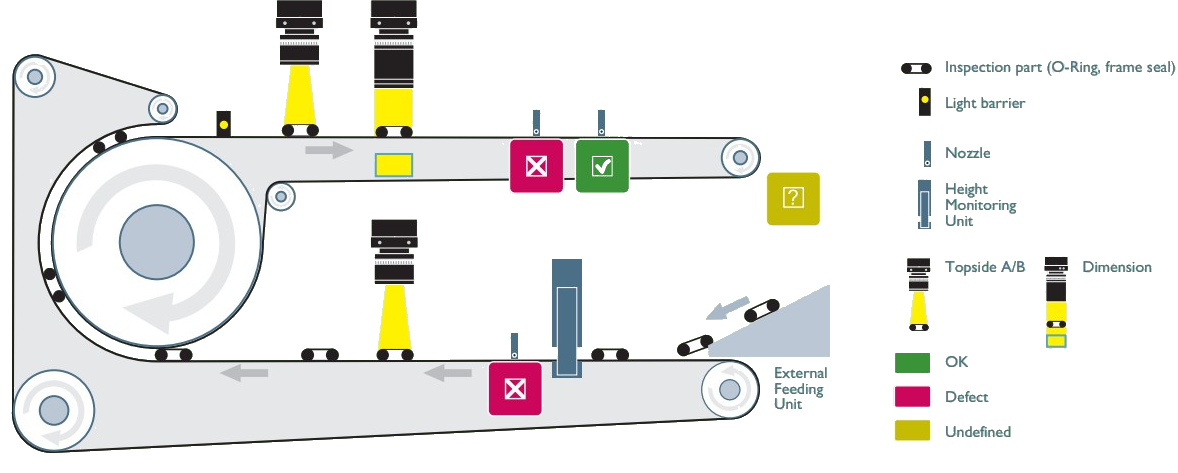

COMPACT2 is the high-performance system for fully automatic quality control of seals in all sizes – efficient, precise and suitable for inline use. Three high-resolution sensors reliably check each sealing ring for dimensional accuracy and surface defects on both sides. With the optionally integrable FASTLINE™ sensor, hidden cracks that only become visible under deformation can also be detected. Thanks to its open conveyor concept, COMPACT2 is ideal for inline use and can be seamlessly integrated into existing production lines. The throughput of up to 12 parts per second enables maximum productivity with the highest inspection accuracy.

100% quality thanks to

industry-leading precision

industry-leading precision

At the core of the COMPACT2 system are cutting-edge 12-megapixel high-resolution sensors that deliver exceptionally precise defect detection. Even the slightest surface defects or dimensional deviations are reliably identified – ensuring zero-defect production, maximum process reliability, and a measurable competitive advantage.

Full-scope quality control

COMPACT2 ensures reliable detection of a broad spectrum of seal defects – including surface damage, imperfections, contamination, as well as burrs and fine cracks.

Technology highlight:

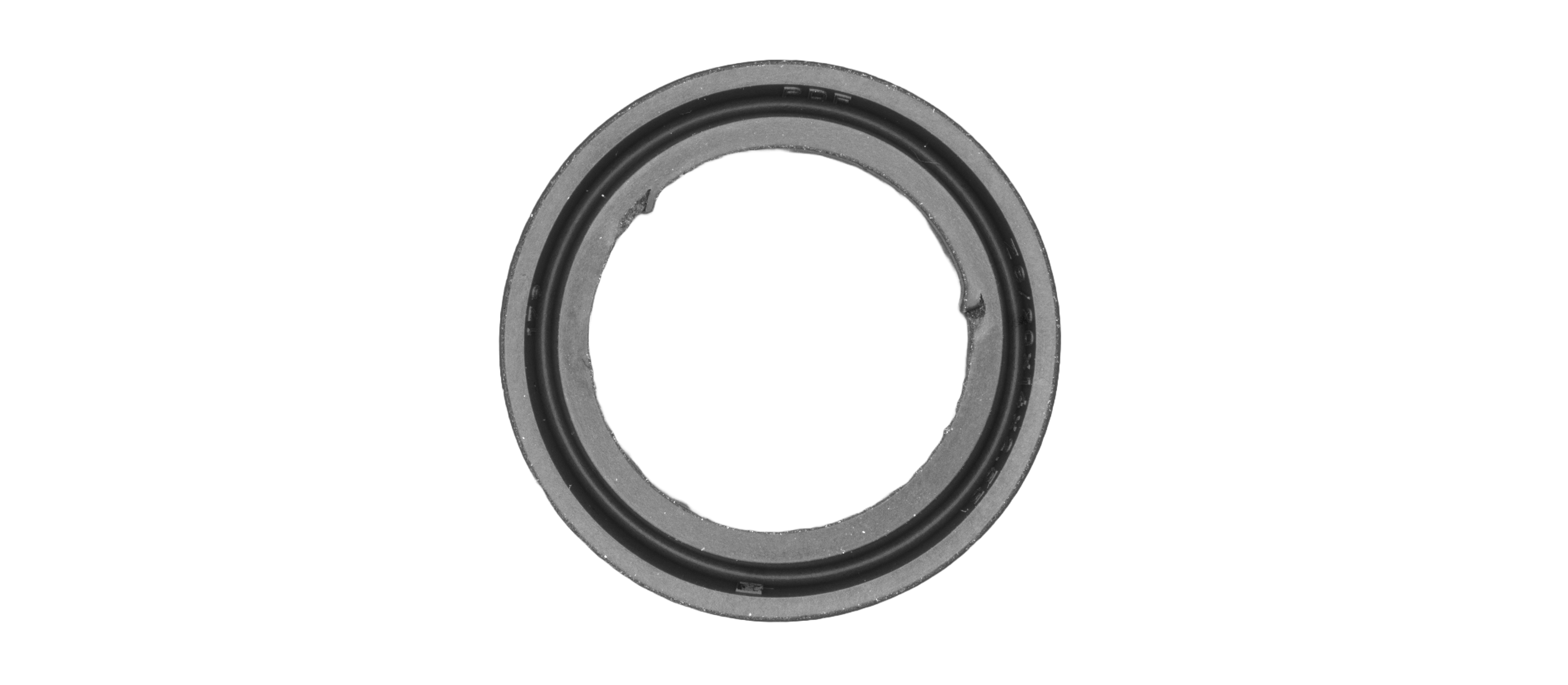

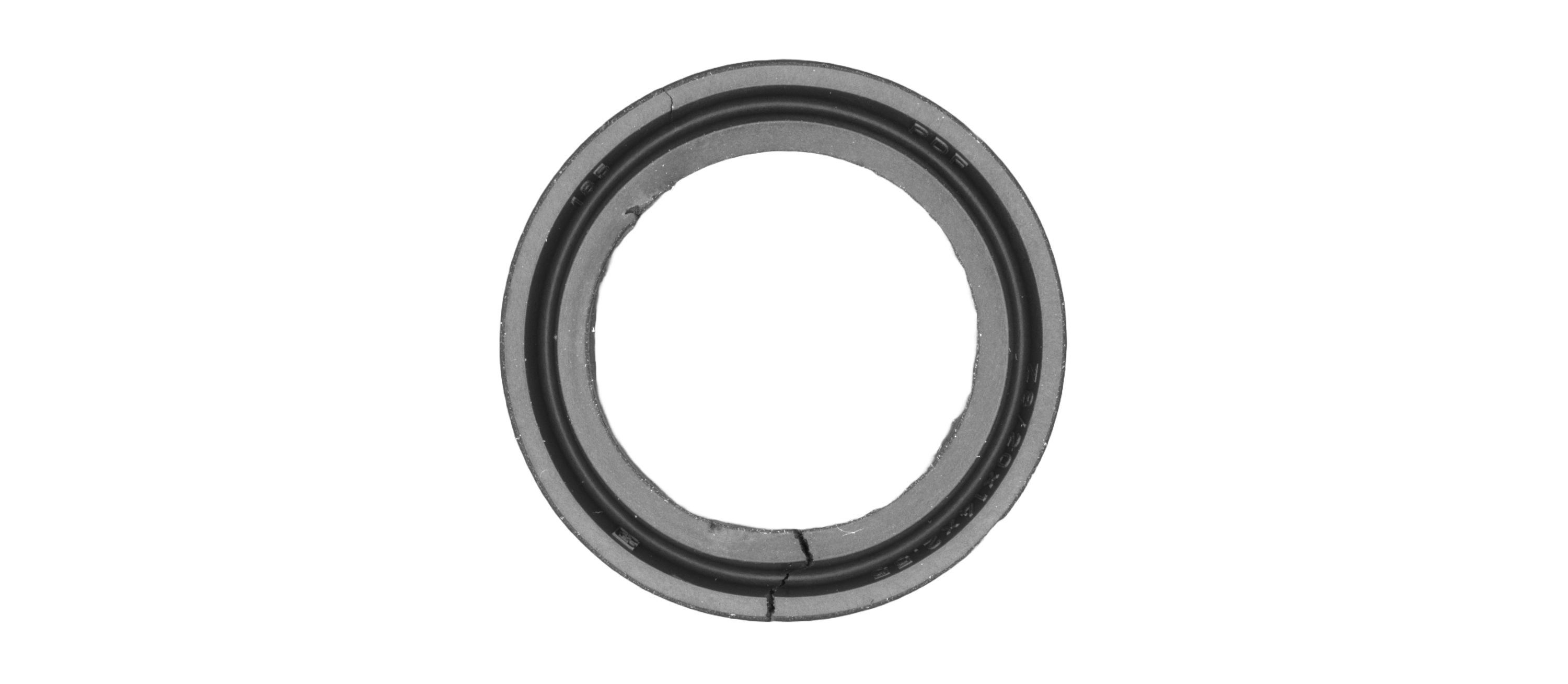

FASTLINE™ crack inspection

FASTLINE™ crack inspection

For maximum product safety, the BASIC2 can be enhanced with the optional FASTLINE™ sensor – capable of detecting even hidden cracks that only appear under deformation. The result: high-end quality assurance that goes beyond standard inspection.

Unbeatable flexibility:

a solution for all seal sizes

a solution for all seal sizes

COMPACT2 inspects seals with outer diameters ranging from 5 to 100 mm and heights of up to 10 mm – ideal for manufacturers with diverse and varied product portfolios.

Optional: Feeder CFS250

For ultra-fast feeding

For ultra-fast feeding

Asentics CFS250 is the fast and precise feeding unit for COMPACT2. The system enables the processing of a wide range of products while maintaining a high and consistent throughput. Product changes can be controlled quickly and completely via the COMPACT2 user interface. In combination with the generously sized parts container, CFS250 is the ideal solution for batch testing large quantities.

Already using a feeding unit? No problem!

COMPACT2 integrates seamlessly into existing systems and production lines.

Your requirements. Our solution.

Your COMPACT2 is developed in close cooperation with you – individually configured and precisely tailored to your inspection parts. Whether sensor technology or software: the focus is on what matters most: your seal and its flawless quality.

COMPACT2 at a glance:

High-performance inspection system for quality control of seals for surface defects and dimensional accuracy

Ultra-fast detection of hidden cracks with FASTLINE™

High throughput of up to 12 parts/second

Suitable for a very wide range of seal sizes

Open feeding concept enables easy integration

Optional: Fast parts feeding with Asentics Feeder CFS250

Your COMPACT2 is already waiting!

Whether you are just starting to automate your quality control or have a specific application in mind, entrust the quality of your seals to COMPACT2 – our team will help you every step of the way.