We provide surface inspection solutions for the most demanding requirements

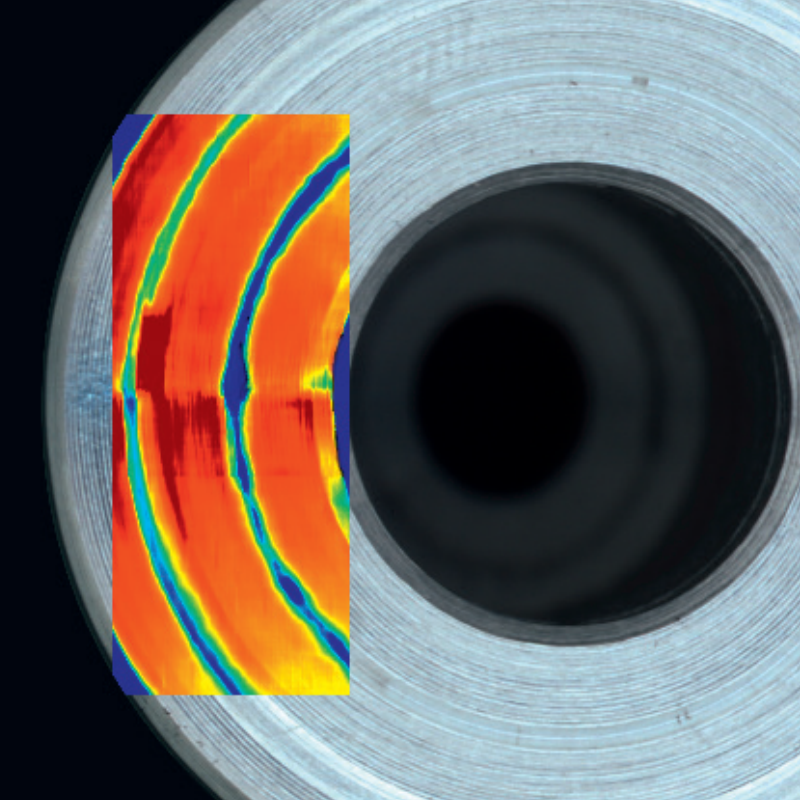

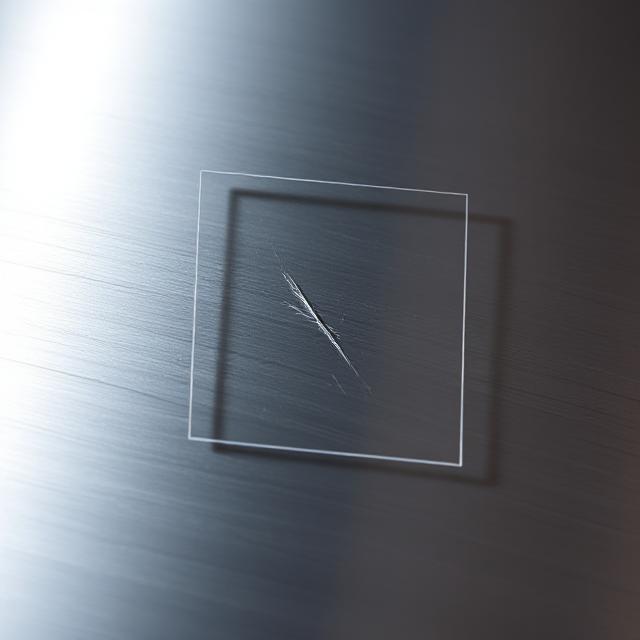

We have been experts in surface inspection for over 20 years. ROOSA™ combines all this expertise in a powerful image processing solution that ensures the quality of your surfaces without compromise. Whether scratches, cracks, or other defects – our AI-supported inspection detects everything more precisely, faster, and more reliably than ever before. ROOSA™ is versatile. Whether you need 2D or 3D inspection or want to check hard-to-reach areas such as cavities, ROOSA™ offers the right surface inspection for quality control. Discover the possibilities.

We provide surface inspection solutions

We have been experts in surface inspection for over 20 years. ROOSA™ combines all this expertise in a powerful image processing solution that ensures the quality of your surfaces without compromise. Whether scratches, cracks, or other defects – our AI-supported inspection detects everything more precisely, faster, and more reliably than ever before. ROOSA™ is versatile. Whether you need 2D or 3D inspection or want to check hard-to-reach areas such as cavities, ROOSA™ offers the right surface inspection for quality control. Discover the possibilities.

The right solution for every application.

Discover the ROOSA™ product portfolio

ROOSA™

Technological advantage

ROOSA™

Technological advantage

What is surface inspection?

Surface inspection for quality control, also known as surface inspection, is an automated process for detecting defects on material and component surfaces. The aim of this inspection is to identify defects such as scratches, cracks, pores, or discoloration at an early stage and to reliably sort them out.

Our high-resolution, intelligent image processing system ROOSA™ is used for optical surface inspection for quality control. The system inspects surfaces without contact, in real time, and with significantly higher precision and speed than manual methods.

Our surface inspection solution for quality control is primarily used in industrial manufacturing—where the highest demands are placed on product quality. It helps to continuously ensure quality, minimize scrap, and sustainably increase production efficiency.