100% inspection of dialysis filters

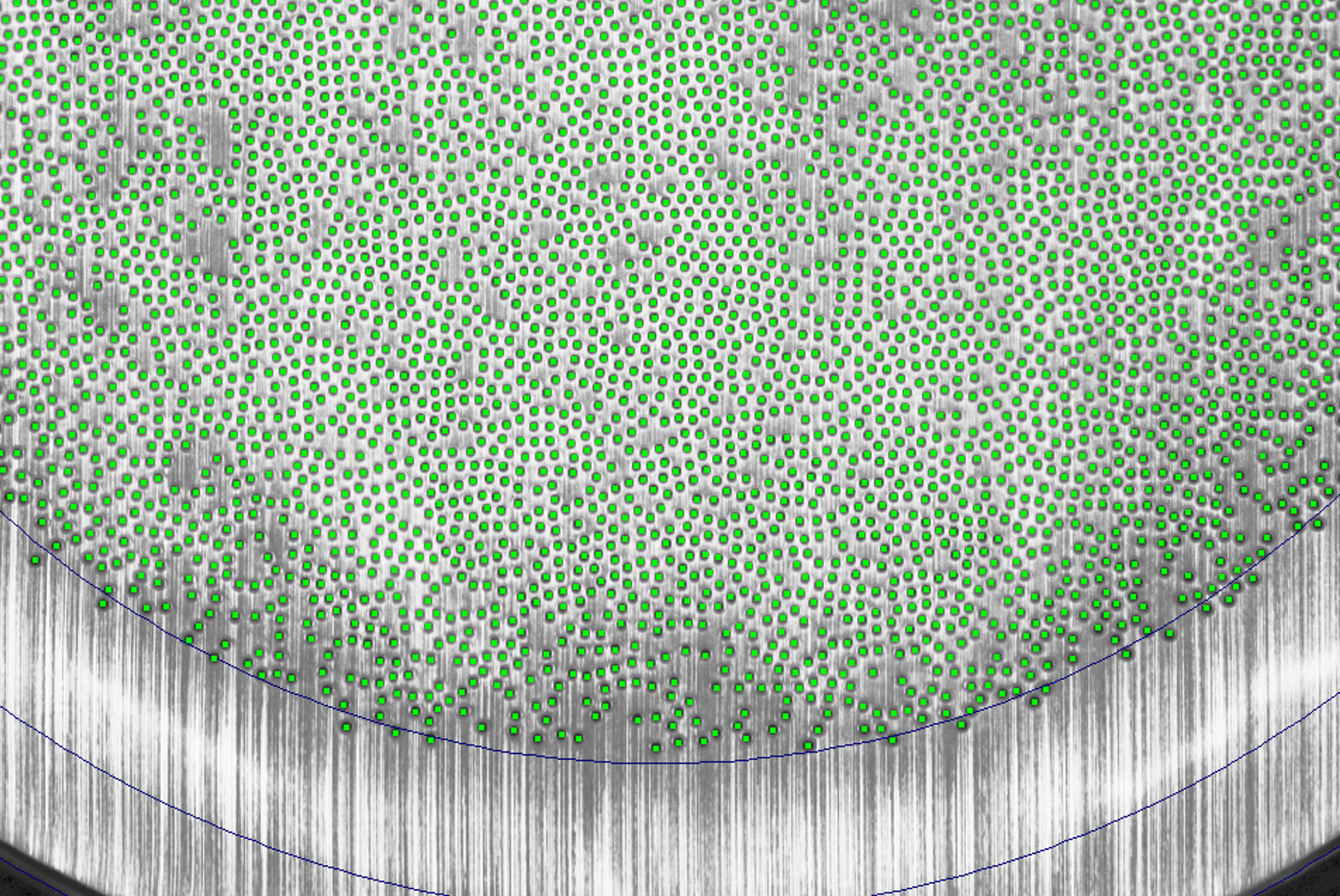

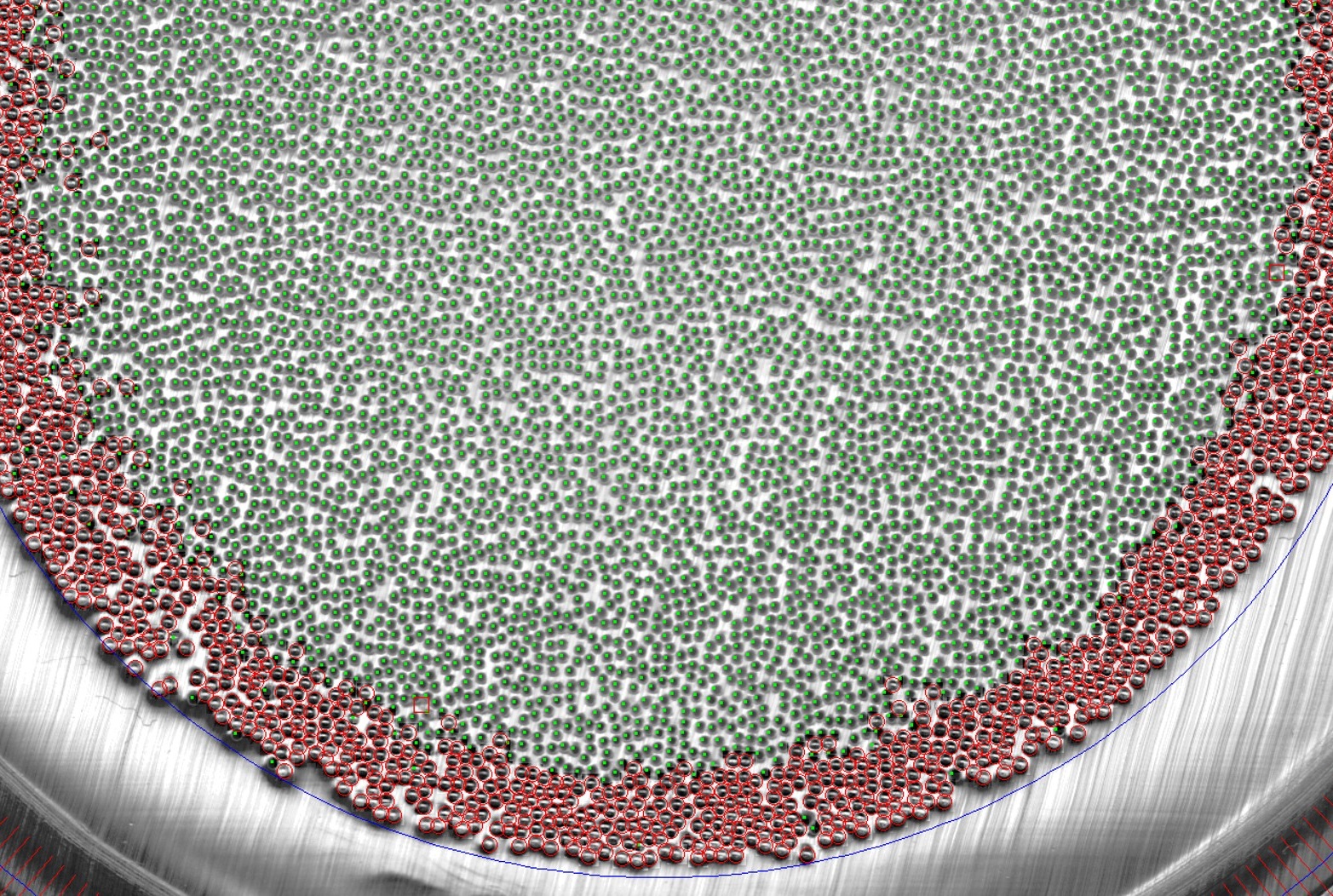

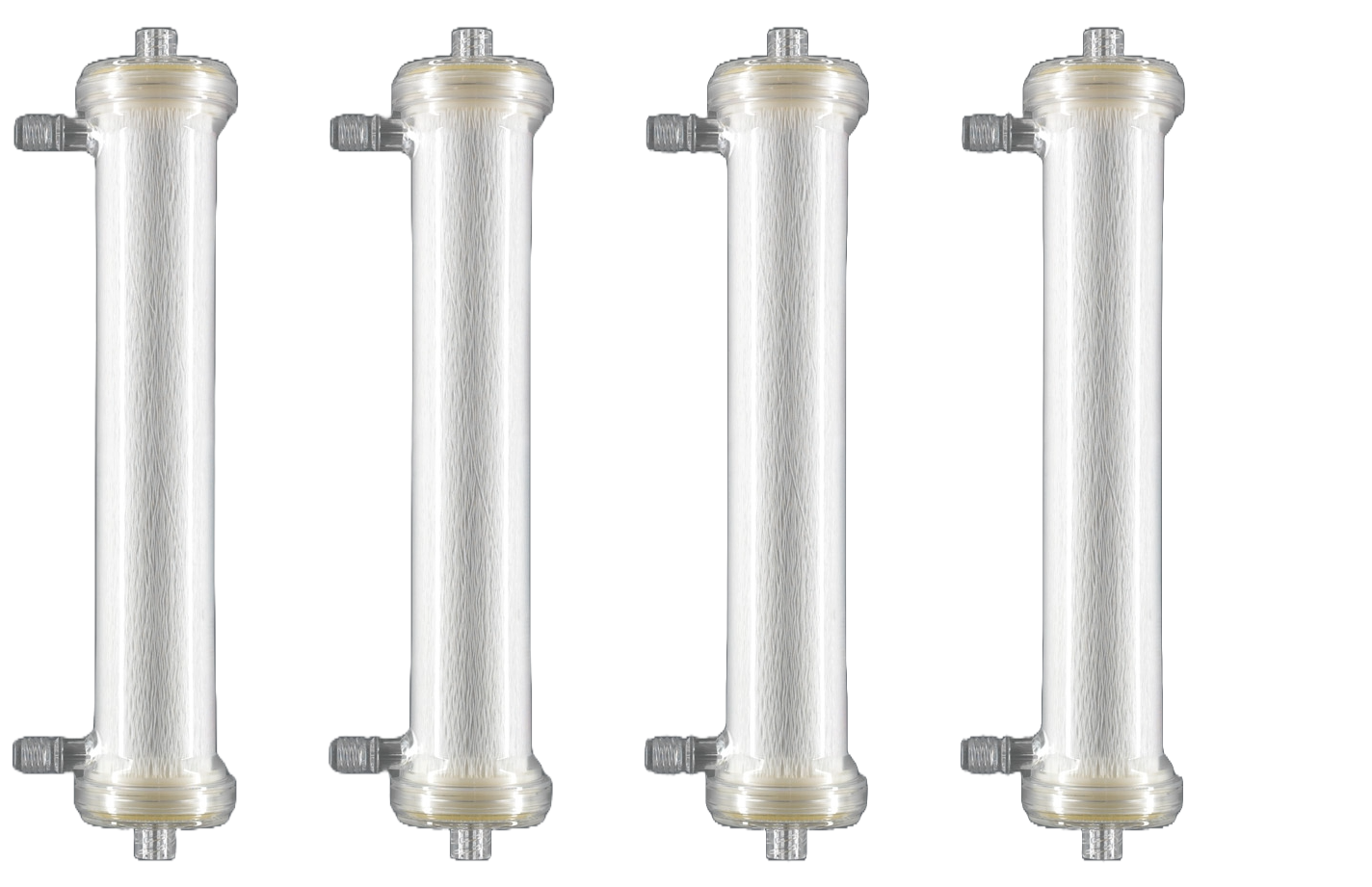

We guarantee the quality of your dialysis filters. SIRPA™ is the leading optical inspection technology for 100% quality control of fine-pored filters. Both filter surfaces are checked with high precision for flatness, openness, the number of filter capillaries, and defects or contamination. The process is fully automated and seamlessly integrated into your production chain.

Every single fibre.

The quality requirements for dialysis filters are high. With SIRPA™, no defective product will leave your production line.

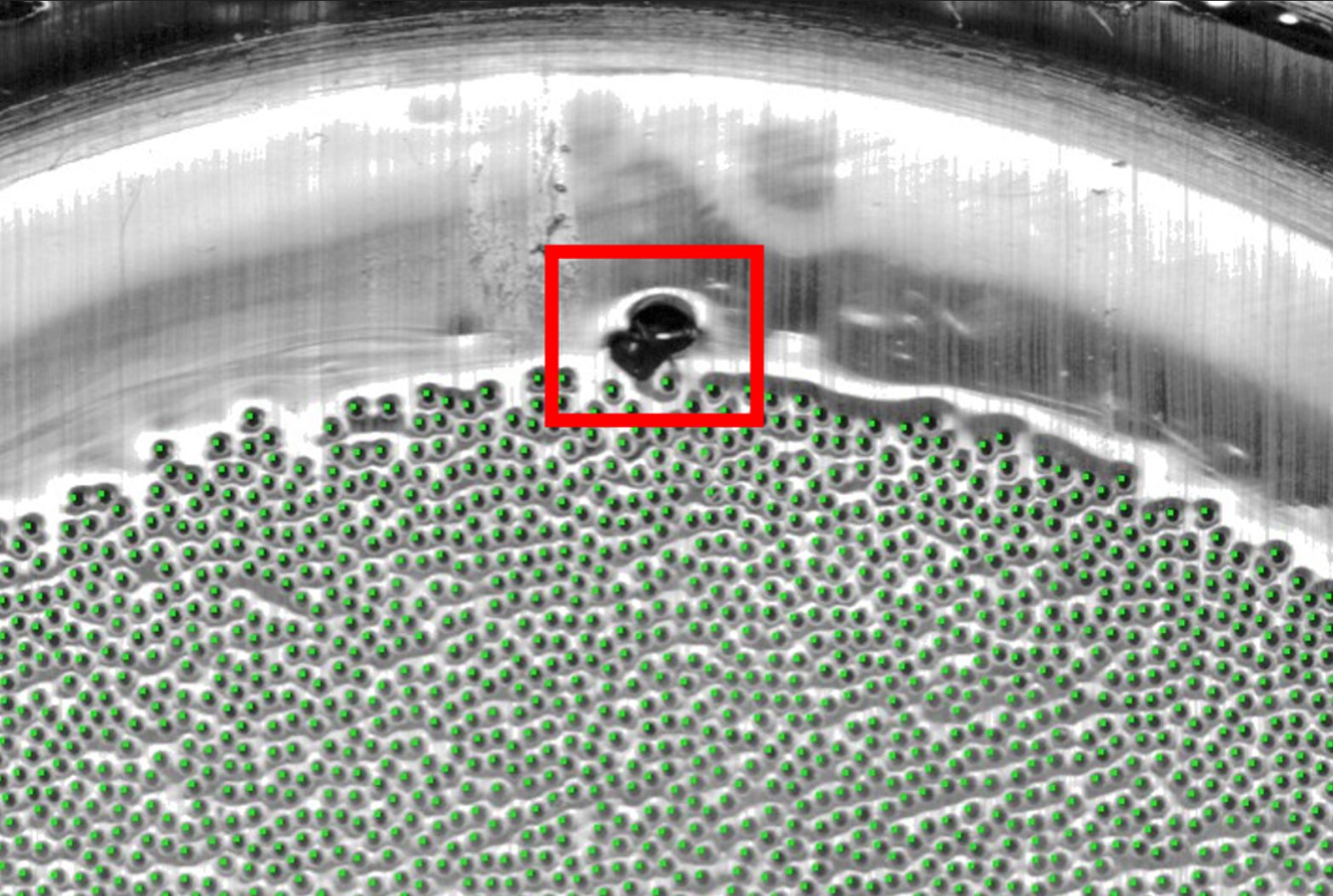

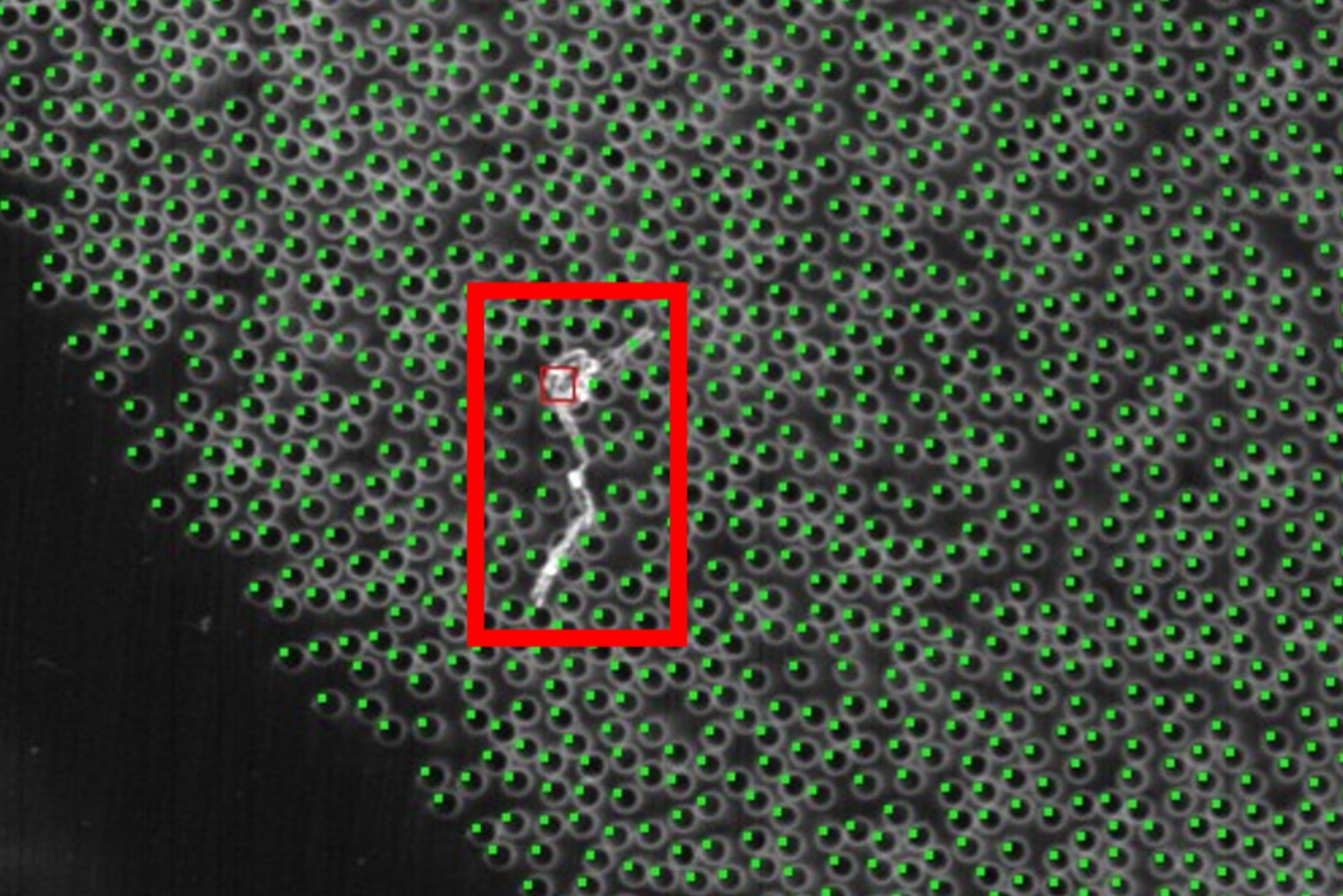

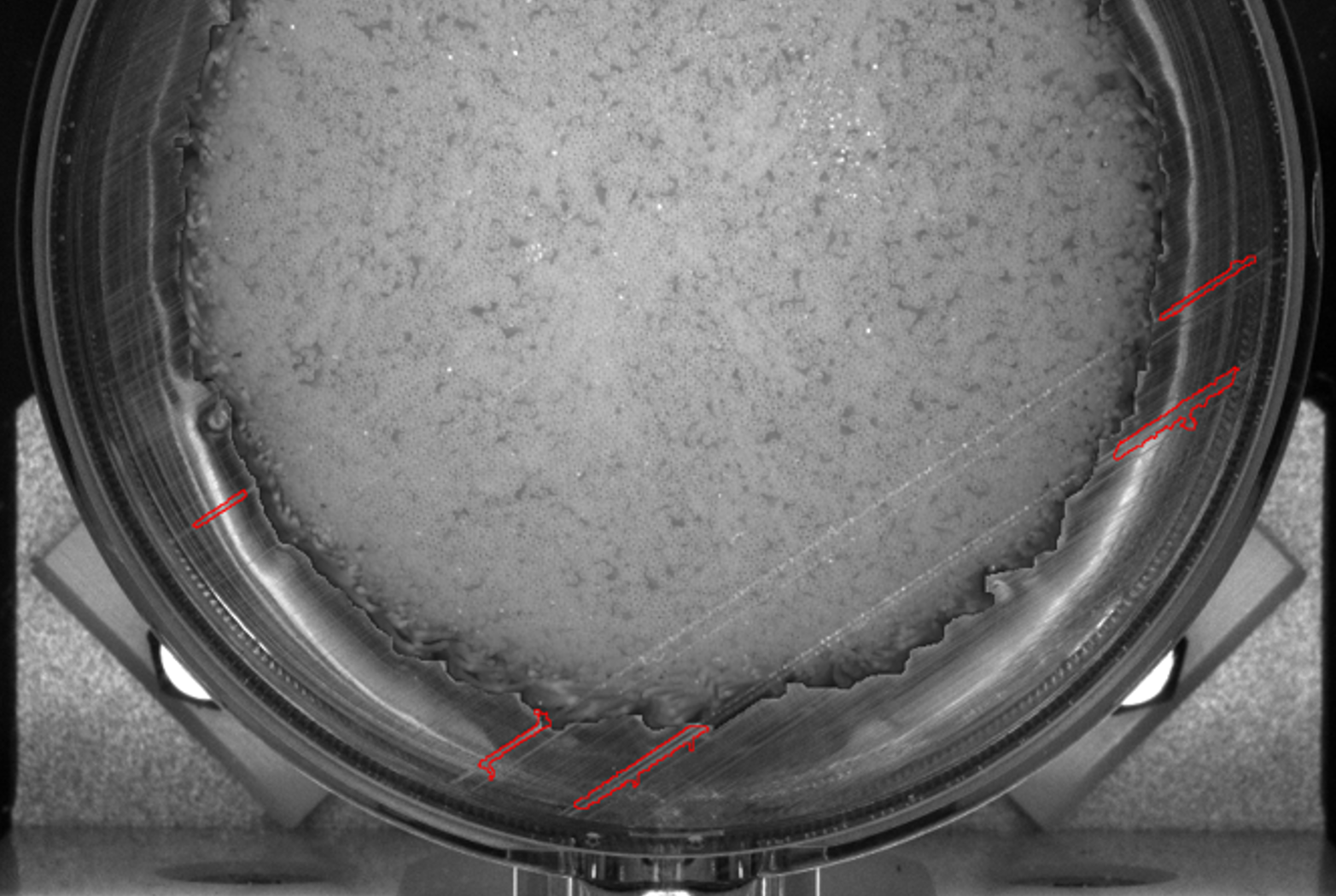

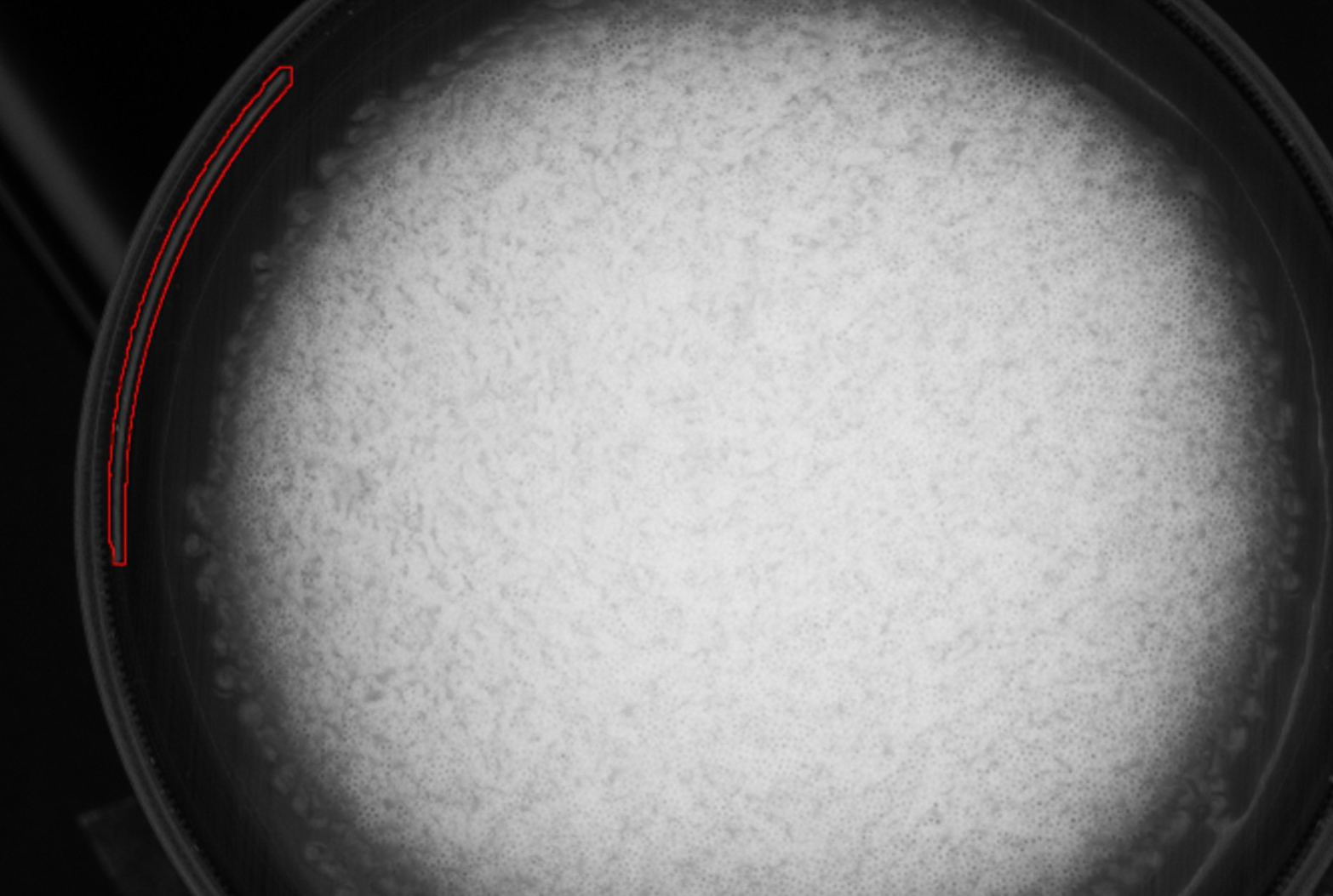

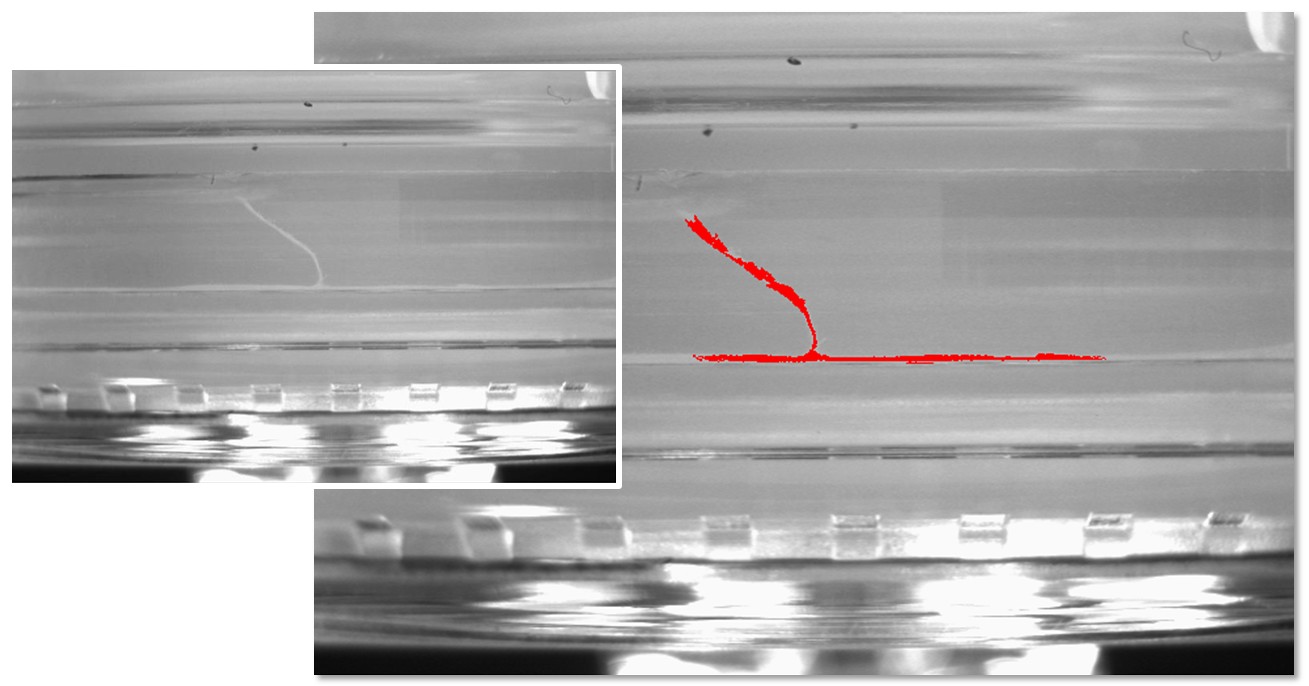

Thanks to its innovative, AI-supported image processing technology, SIRPA™ inspects every single fibre and reliably detects whether it is closed or has other defects – with high precision and at ultra-fast speed.

Inspection from A to Z

SIRPA™ ensures the quality of both filter surfaces comprehensively and reliably. As well as counting fibres and checking for closed or deformed fibres, SIRPA™ also detects other defects, such as contamination, bubbles in the sealing surface, and cutting grooves.

SIRPA™: Growing flexibility

Your product range varies and grows – quality testing remains the same. SIRPA™ was developed to adapt effortlessly to the diversity of your dialysis filters. Whether different sizes or geometries, SIRPA™ ensures the quality of your products today and tomorrow.

The All-In-One system

Automate your quality control processes! The ITC-SIRPA™ system provides everything required to boost efficiency immediately. Alongside the high-precision SIRPA™ optical modules, the system features a specially designed conveyor system for fast and easy filter handling. Thanks to its compact design and standardised interfaces, the entire system can be easily integrated into your existing production line, both physically and digitally. The control cabinet features an intuitive operating terminal that enables full system control with maximum user-friendliness..

SIRPA™ guarantees the quality of dialysis filters around the world

To remain competitive in the global market, it is essential to meet international quality standards. SIRPA™ is the ideal solution for ensuring that your products maintain a competitive edge and establish unprecedented benchmarks in their field.

Meets the highest standards

The production of dialysis filters demands the highest standards, both in manufacturing and in documentation. SIRPA™ is fully compliant with FDA 21 CFR Part 11, meaning that all electronically recorded information is tamper-proof, traceable, and can be audited at any time.

Flexibly expandable

Do you require more than one fibre inspection? We will develop a customised solution that fulfils all your specifications to ensure the quality of your filters.

For example, it is also possible to inspect filter caps or filter housings for particles and damage.

ITC-SIRPA™ at a glance

AI-supported 100% inspection of dialysis filters

All-in-one solution with conveyor system and control cabinet

Suitable for a wide range of filter types and sizes

Reliable detection of all types of defects on dialysis filters

High throughput thanks to minimal cycle time (1440 parts/hour)

Easy integration into existing production lines

Your ITC-SIRPA™ is waiting!

Whether you are just beginning to automate your quality control processes or have a particular application in mind, trust ITC-SIRPA™ to ensure the quality of your filters. Our team will support you throughout the process.