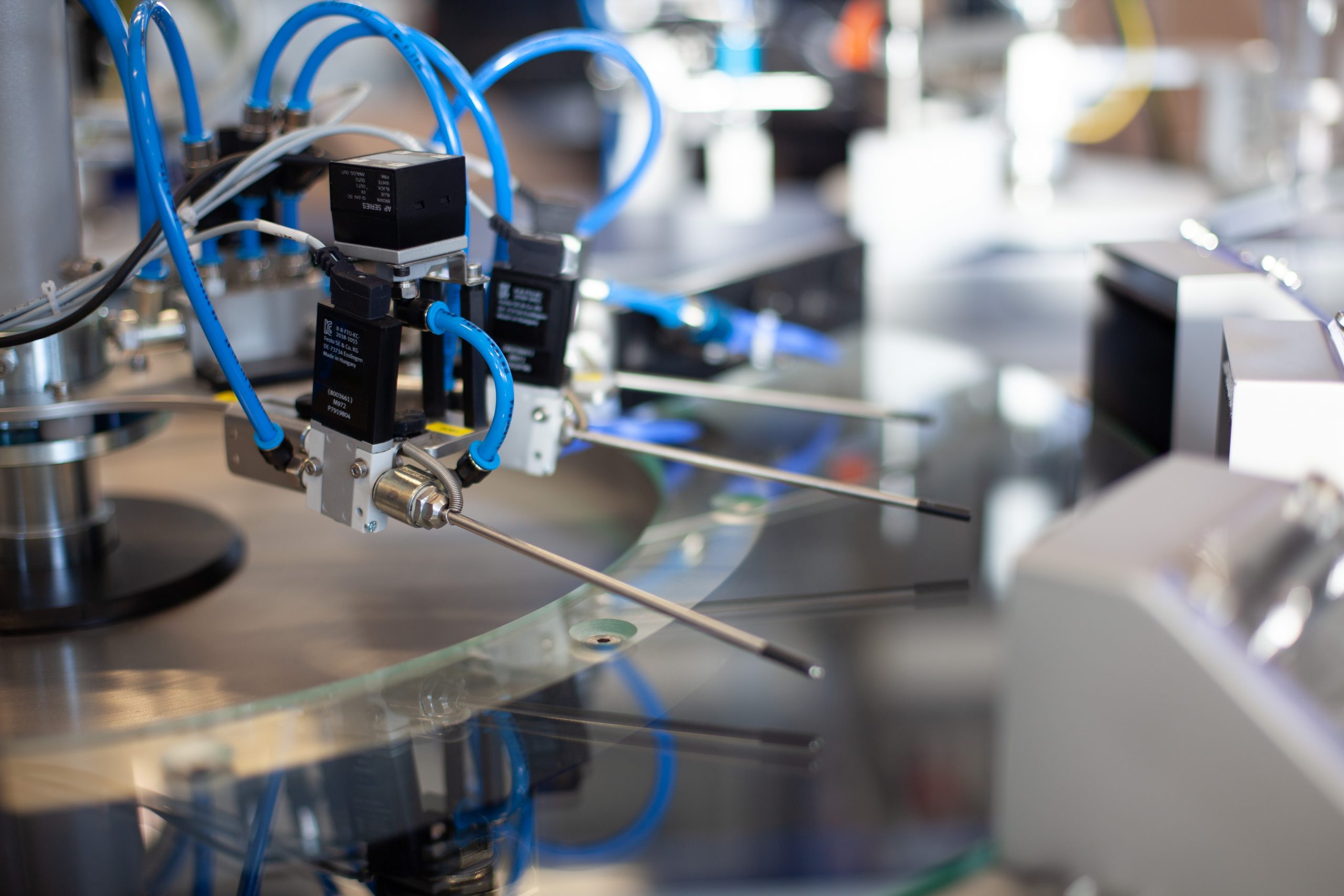

The most powerful sealing inspection

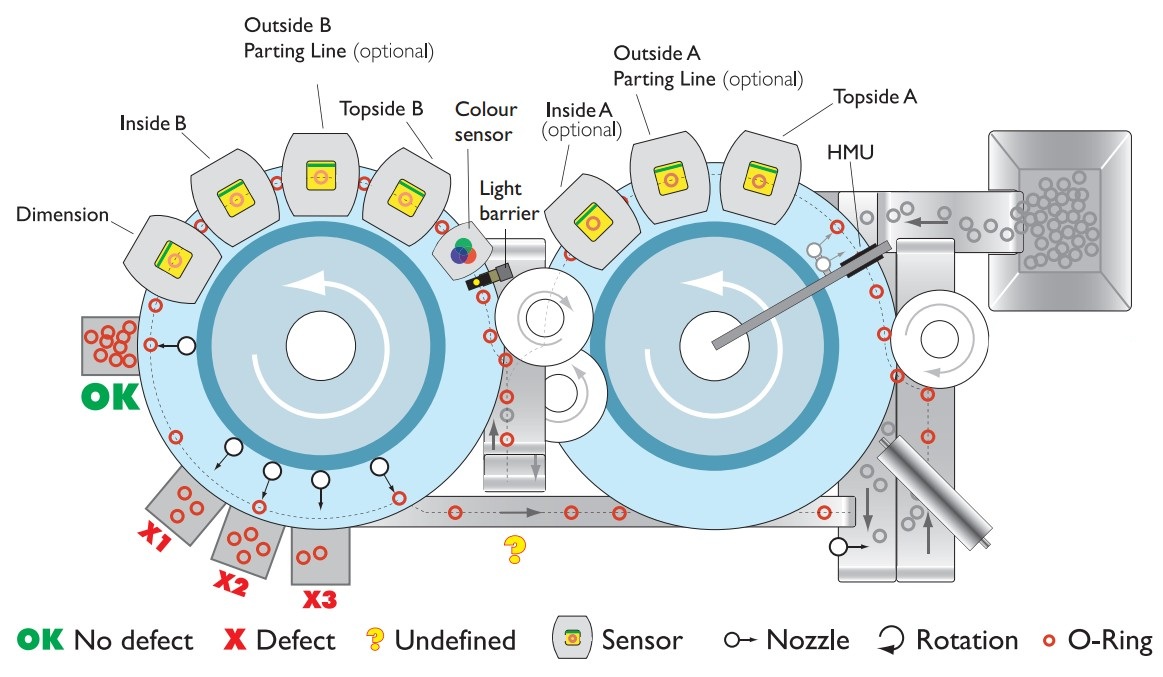

VARIO4 is the high-performance system for fully automatic 360° inspection of rotationally symmetrical seals. With up to eight optical sensors, each sealing ring is thoroughly checked for surface defects and dimensional accuracy. Thanks to its innovative inspection concept, VARIO4 achieves an impressive inspection rate of up to 12 parts per second – for maximum efficiency and uncompromising quality assurance.

100% quality thanks to

industry-leading precision

industry-leading precision

At the core of the VARIO4 system are cutting-edge 12-megapixel high-resolution sensors that deliver exceptionally precise defect detection. Even the slightest surface defects or dimensional deviations are reliably identified – ensuring zero-defect production, maximum process reliability, and a measurable competitive advantage.

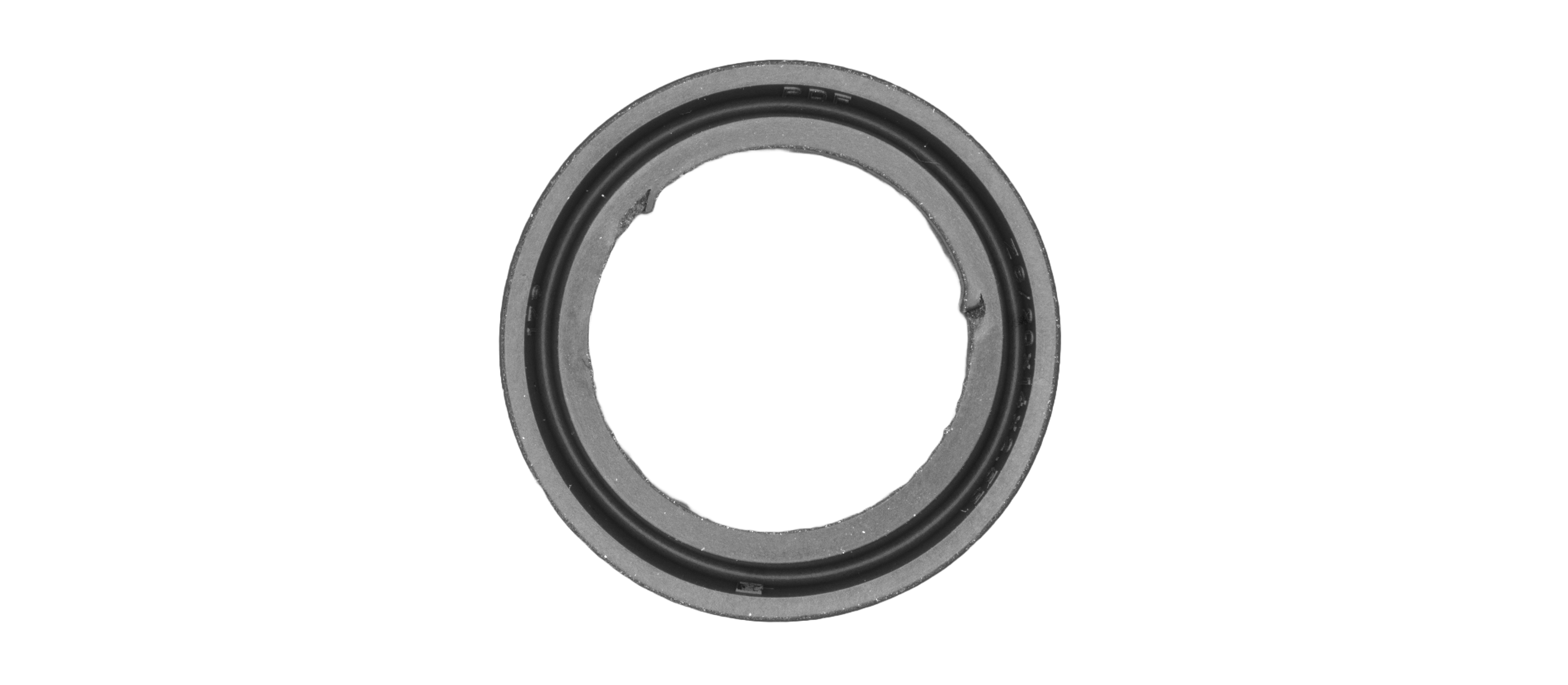

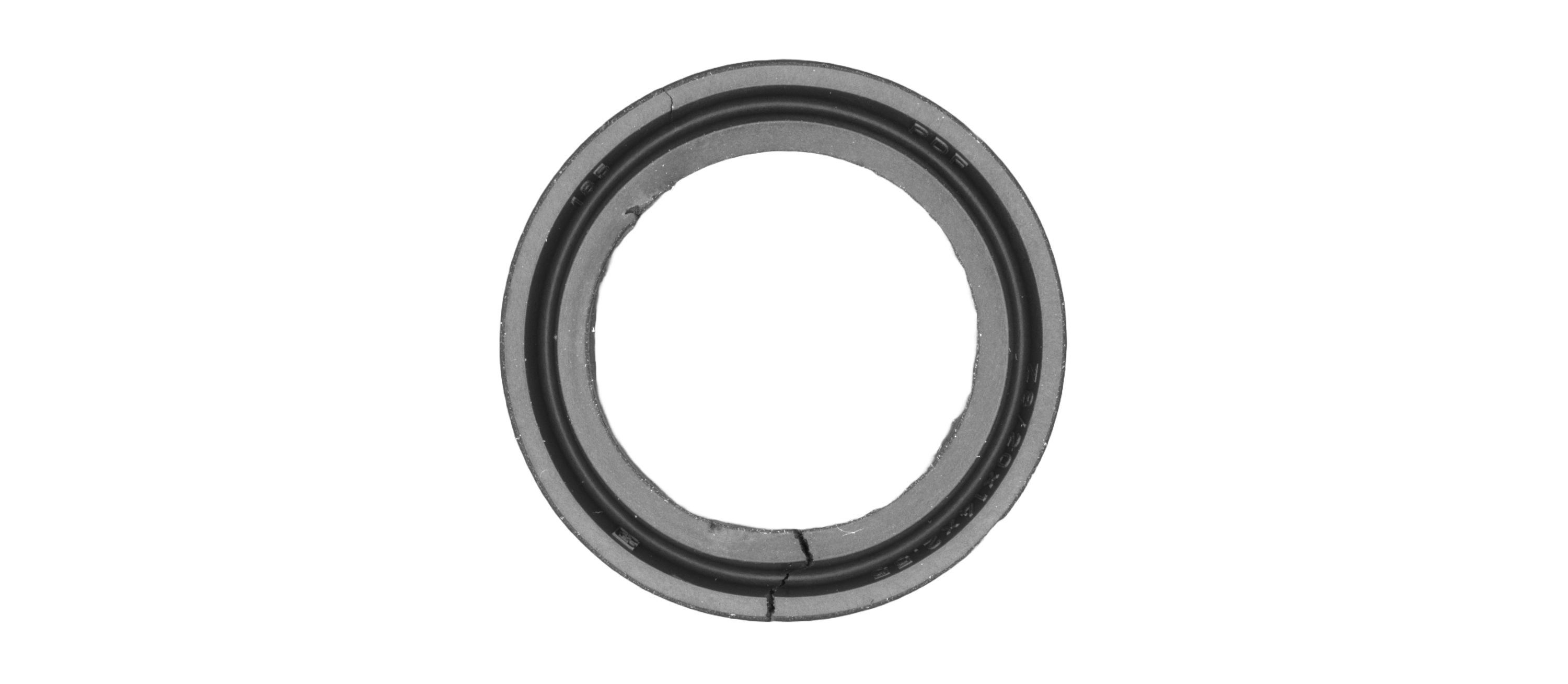

Full-scope quality control

VARIO4 ensures reliable detection of a broad spectrum of seal defects – including surface damage, imperfections, contamination, as well as burrs and fine cracks.

Flexibility in every aspect

VARIO4 can be quickly and easily configured for new product types. All the necessary parameters are stored digitally and can be accessed at any time, enabling quick set-up and reducing downtime.

VARIO4 also offers specific defect sorting (SDS). Defective parts are sorted separately based on the type of defect (e.g. surface defects, dimensional deviations or colour irregularities). This improves transparency regarding the causes of defects and supports the optimisation of manufacturing processes.

Custom-engineered to fit your exact needs

We work closely with you to tailor the VARIO4 to your exact specifications – from selecting optical sensors and customized software options to integrating extras like the Asentics Airbox, which ensures a dust-free inspection environment. The result is a solution perfectly aligned with your product and quality requirements.

Designed for a wide range of seals

With VARIO4, you can inspect all types of rotationally symmetrical seals. The system handles seals with outer diameters from 5 to 50 mm and heights up to 9 mm, and is compatible with all common elastomers.

Ready for today,

built for tomorrow

built for tomorrow

With ASENTICS, you will be among the first to exploit the full potential of current and future innovations and technologies.

This also applies to digital twins. As a member of the Industrial Digital Twin Association (IDTA), you benefit from all the opportunities digital twins offer, especially in service and maintenance.

VARIO4 at a glance:

High-performance inspection system for the 100% quality control of rotationally symmetrical seals

Ultra-precise, AI-supported detection of surface defects and dimensional accuracy control

High throughput of up to 12 parts/second

Suitable for a wide range of seal sizes

Simple configuration of new product types

Maximum investment security thanks to OPC UA and digital twin

Your VARIO4 is already waiting!

Whether you are just beginning to automate your quality control processes or have a particular application in mind, trust VARIO4 to ensure the quality of your seals. Our team will support you throughout the process.