Application Note

Check & Sort of rotationally symmetrical flat seals

Overview

Flat gaskets are axial-static seals that are indispensable for preventing leakage in closures and groove or flange connections.

For proper function, the shape of the seal must be flawless, as even minimal geometric defects or material chipping can have a significant impact on the sealing properties.

In most cases, a complex and costly surface inspection is not necessary.

In the overall picture, the focus is on a cost-effective inspection system that only tests the functionally relevant properties at maximum throughput.

The inspection of the sealing shape is critical

Surface inspection of the front and outer sides is not required

An economic solution is necessary

Solution

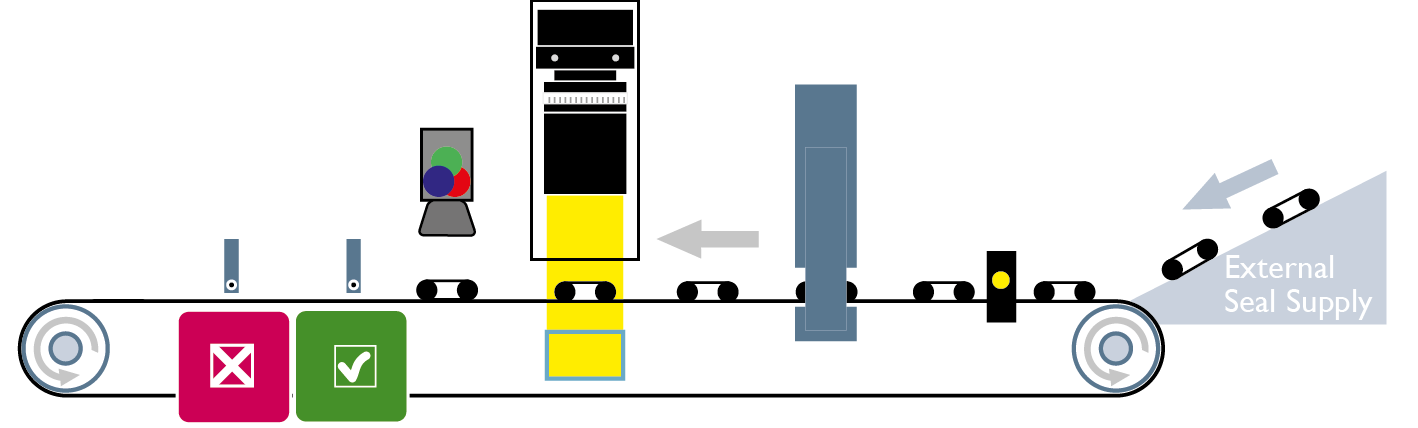

The inspection and sorting of flat seals is a core task of the Asentics EASY. The dimension sensor checks the dimensional accuracy and completeness of the seals; all defects due to under- and over-moulding as well as residual burrs are reliably detected.

If the height is also relevant, the EASY can be equipped with the Height Monitoring Unit (HMU), which determines not only the height but also the waviness of the seals. Furthermore, a colour check is also possible by means of a colour check sensor.

The EASY works with a large field of view of up to 100mm. For maximum cost efficiency, the high throughput of up to 15 parts/s minimises inspection costs per part. The sensor resolution is adapted to the application and is 5MP

This Application Note is available for download as PDF: Application Note EASY 1.1 check&sort