Application Note

360° inspection of Cable Grommets

Overview

Similar to other seals, grommets must be checked for surface defects from both the upper and lower side.

A classic test system with two plates and a turning station is often not the optimal solution. Due to the characteristic geometry, the grommets are only stable on one side and turning and testing on a second glass plate is not possible

The component is only stable on one side

Surface inspection for both sides required

Component unsuitable for turning

Solution

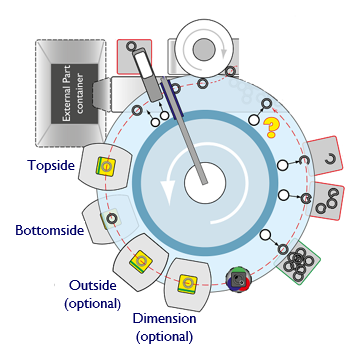

The BASIC2 equipped with a topside and bottomside sensor can check both the lower side and the upper side of grommets. Thanks to the bottom-side sensor, a transparent glass plate and specially adapted lighting, the double-sided inspection is carried out without having to turn the grommets.

Optionally, the dimensional accuracy can be checked with the dimension sensor and even the outer wall surface with the outside sensor. The result is a system for a complete 360 ° inspection of grommets.

The BASIC2 is available in two versions. While the BASIC2-50 works with a 50mm field of view, the BASIC2-70 offers a 70mm field of view. The optics of both versions operate with a high resolution of 12MP and the throughput is typically 3-5 parts / second.

If you have any questions or are interested in the 360 ° inspection of cable sleeves, give us a call +49 (0)271/303 91-0 or