The next generation of industrial image processing

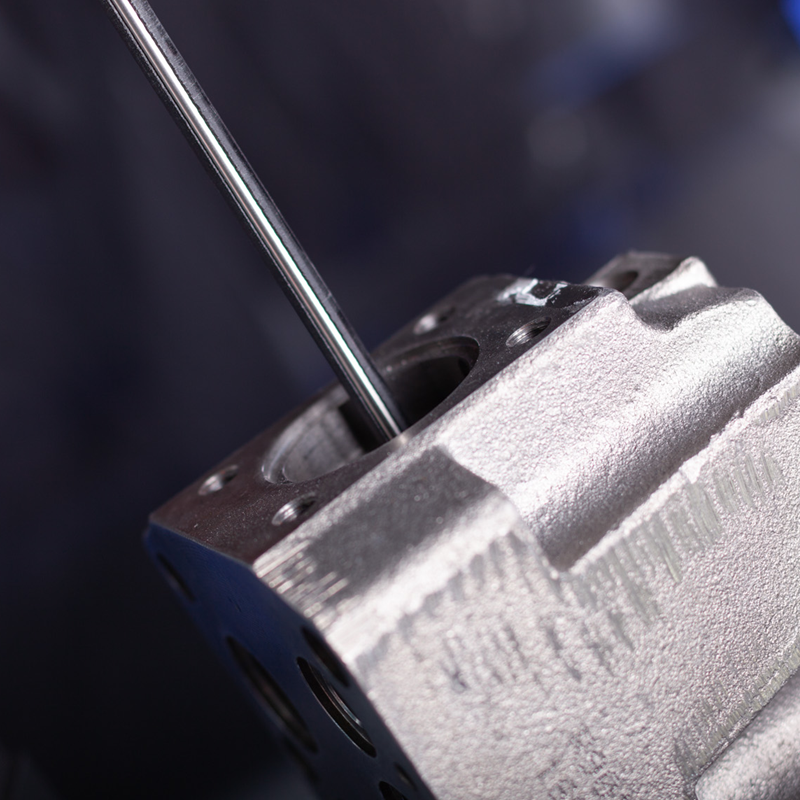

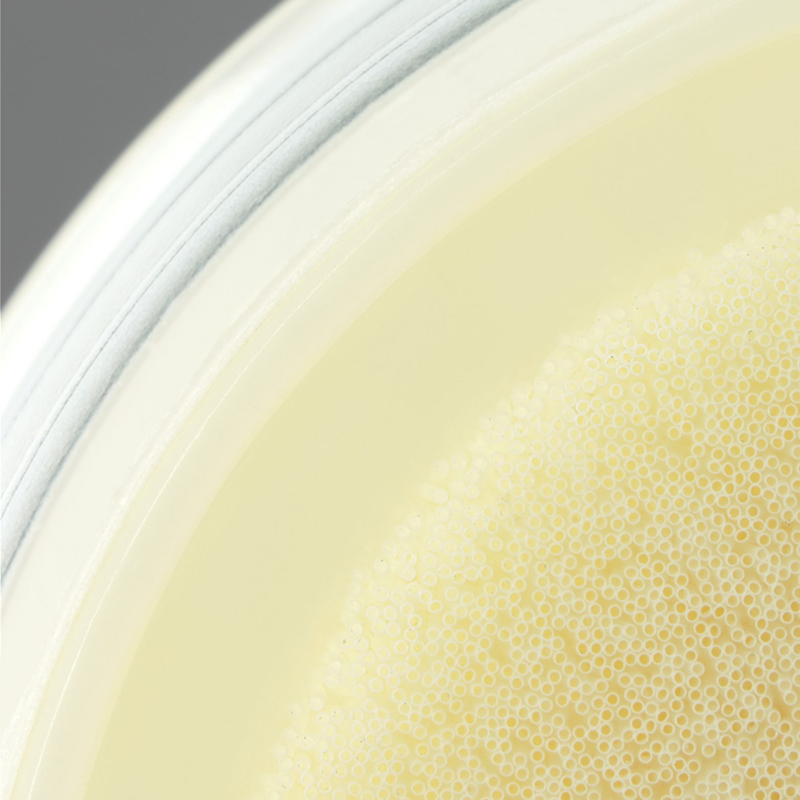

In modern manufacturing, efficiency is no coincidence — it is the result of intelligent automation. Machine vision plays a key role in this process. At ASENTICS, we develop high-performance machine vision systems that set new standards in industrial quality control, metrology, and process optimization. Our tailored solutions capture, analyze, and evaluate products with maximum precision — whether for surface inspection, dimensional accuracy checks, the testing of complex seals, or the inspection of sensitive components such as dialysis filters. In this way, we help companies make their manufacturing processes more efficient, ensure long-term quality, and measurably increase productivity.

The next generation of industrial image processing

In modern manufacturing, efficiency is no coincidence — it is the result of intelligent automation. Machine vision plays a key role in this process. At ASENTICS, we develop high-performance machine vision systems that set new standards in industrial quality control, metrology, and process optimization. Our tailored solutions capture, analyze, and evaluate products with maximum precision — whether for surface inspection, dimensional accuracy checks, the testing of complex seals, or the inspection of sensitive components such as dialysis filters. In this way, we help companies make their manufacturing processes more efficient, ensure long-term quality, and measurably increase productivity.

A solution for everything

Our product solutions represent only a portion of what we accomplish at ASENTICS. In addition to other systems for specific inspection tasks – such as completeness checks, part verification, position detection, or print image inspection – we continuously develop new technologies and approaches to meet future requirements. A particular focus lies on the growing field of AI-based machine vision, enabling us to make industrial quality control even smarter and more efficient.