The ITC ROOSA Inside – Setting a new standard in cavity inspection capability

The ITC ROOSATM Inside is our new complete system for the surface inspection of cavities. Gain a deeper insight into the functionality, technical data and possibilities offered by the ITC ROOSATM Inside Inside:

The ITC ROOSATM Inside is a fully fledged solution for the surface inspection of cavities. The system includes an inspection cell with optics and parts handling, as well as a control cabinet including the results display.

While inspection systems of this class are usually loaded fully automatically or manually, the ITC ROOSATM can be operated stand-alone or, true to the motto “ready to integrate”, inline. The operating mode can even be changed within a few minutes.

Cavities have two properties, the combination of which presents a complex challenge for image processing:

The limited space available

The large range of cavity geometries

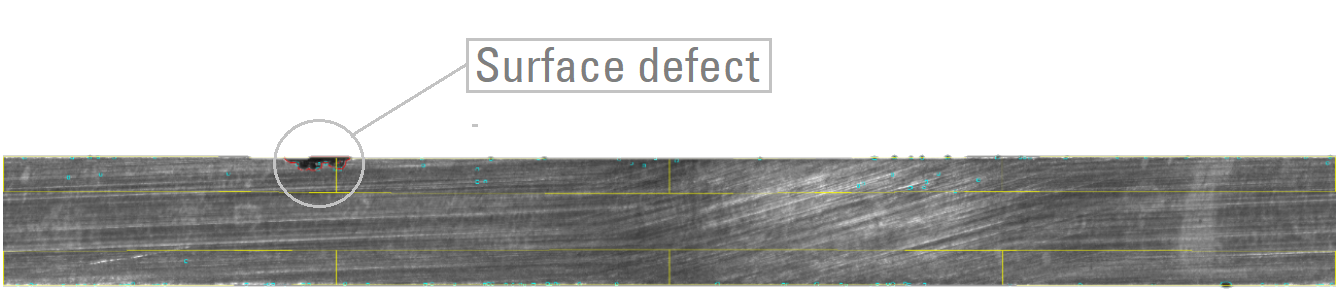

In order to be able to detect defects at all, cavities must be adequately illuminated during image acquisition. Especially in surface inspection, the inspection success depends on the type of illumination used. Ideally, illumination from the side creates a “shadow”, which makes the detection of defects (scratches, cavities, pores) possible in the first place. Accordingly, it is understandable that simple incident light from common endoscopes is insufficient for obtaining qualitative surface images. However, the diameters of the cavities to be inspected can only be a few millimetres. Accordingly, a complex image processing solution is required whose optics provide the necessary exposure, taking into account the tight space conditions.

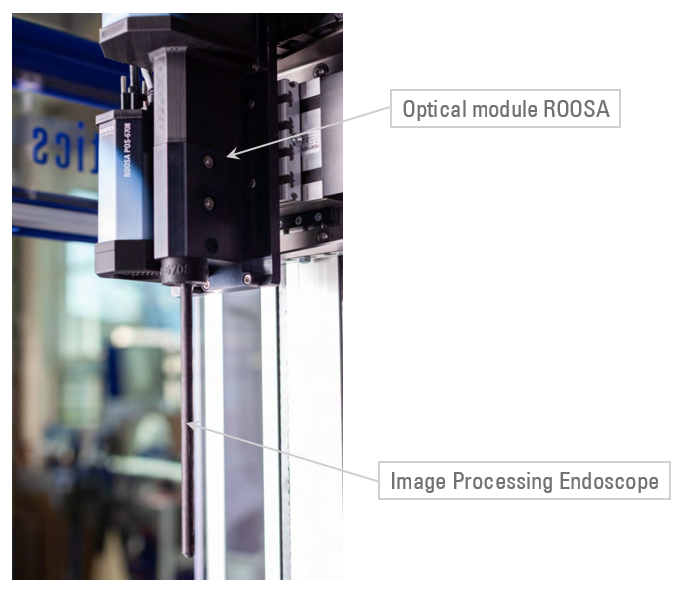

The technical connection between the ROOSATM optical module + ASENTICS Image Processing Endoscope makes it possible.

ASENTICS ROOSATM: Our optical module for surface inspection with extremely high resolution for detecting the smallest surface defects such as grooves, scratches or blowholes, with the additional option of monitoring dimensional accuracy.

ASENTICS Image Processing Endoscope: The key factor in cavity inspection. The sophisticated combination of endoscope and illumination creates the basis for overcoming the described image processing challenges. The result are inspection images that are remarkable in their quality compared to the usual images of cavities and enable the detection of defect sizes far above the industry standard. In addition, all of our image processing endoscopes are custom-made and tailored to your application in all essential parameters (e.g. length, diameter, viewing angle and illumination arrangement).

All surface defects relevant in practice, including:

Scratches

Grooves

Blowholes

Outbreaks

Impurities

Corrosion

Our optical modules are flexible with regard to the optical components, and the ROOSATM Inside is no exception in this respect. For reliable detection of particularly small defects, we recommend a resolution of 7µm.

The ITC ROOSATM Inside can be used flexibly with regard to the operating mode. It can be operated stand-alone as well as inline. The optical inspection process is divided into four consecutive steps:

- The ITC ROOSA Inside is loaded with a test part

1.1 Manually in stand-alone mode by a person.

1.2 Fully automatic in inline mode by a robot.

- Collision Avoidance and Test part identification

The ITC ROOSA InsideTM is equipped with an independent optics module for position control and a test part identification. The following criteria are checked before lowering the endoscope:

-

- The test part is in the predefined position

- Checking the cavity contour

- Identification of the test part

- Image Acquisition

The endoscope enters the cavity. The image acquisition starts and the test part is rotated by 360°C. The result is an inspection image that covers the entire inspection area.

- Evaluation and Unloading

Based on the preset parameters, the test part is evaluated as OK or NOK. The specifications regarding the defect sizes to be detected can be configured effortlessly via the user software. The test result is visually displayed and the test part can be…

4.1 …manually transferred to the subsequent process in stand-alone operation.

4.2 …automatically transferred to the subsequent process via robot in inline operation.

This and further information about ITC ROOSATM Inside can be found in the Infosheet.

Are you interested in ITC ROOSA Inside or do you have any further questions? Simply call us at +49 (0) 271 / 303 91-0 , or